lspotts38

Aluminum

- Joined

- Mar 7, 2012

- Location

- Northcentral Pennsylvania

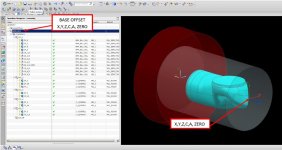

I have a few questions about getting machining geometry setup in NX for 5 axis work. I am able to get code that works, but seems like I might be missing something in the setup of the machining geometry for 5 axis work. I am using fixture tracking in the below outlined. Currently, I setup a base offset at a known location on the part, see first image. Make that my top level work MCS, set to "MAIN" in the MCS dialog. When I work on any other A or C axis index, I make a new MCS under the main MCS, set to "LOCAL" and special output to "USE MAIN MCS". I then have to rotate the "local" MCS to what the machine would see for X,Y & Z orientations. It works, but it seems pretty clunky to me. Thing that makes me most nervous about this setup is the possibility of not getting the X,Y & Z axis projections correct on indexes that use both "A" & "C", I could see where it would get challenging on compounded surfaces. I have looked for videos on NX CAM programming, and havent really come up with much as far as the setup that is required to post good code. Anyone able to give me a few tips? Posted this originally in the CAD/CAM forum but doesn't seem to be much traffic over there. Thanks in advance.