Richard/SIA

Cast Iron

- Joined

- May 13, 2007

- Location

- No. Nevada

Only have a three-axis Fadal mill.

Finally about to have time to do a project for myself!

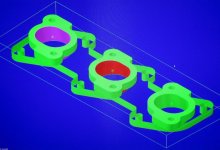

Motorcycle ITB's to Porsche IDA-3 manifold adapters.

The ITB's are oval, the Porsche intake is round.

The ITB oval is narrower than 40mm in Y but longer in X.

So the taper at X is simple but the slight undercut in Y has me wondering about using a lollipop mill?

Aluminum plate, the transition is only .750" deep and 40mm at the bottom.

I've found 3/8" cutters at a decent price.

I'm told that programming this would be a Bear, why?

I could just flip the part and make the blend from both sides but I think setup and cycle speed would be faster if I can do most of it from one side.

Price of the cutter aside, what is the advice on these cutters and this operation?

Finally about to have time to do a project for myself!

Motorcycle ITB's to Porsche IDA-3 manifold adapters.

The ITB's are oval, the Porsche intake is round.

The ITB oval is narrower than 40mm in Y but longer in X.

So the taper at X is simple but the slight undercut in Y has me wondering about using a lollipop mill?

Aluminum plate, the transition is only .750" deep and 40mm at the bottom.

I've found 3/8" cutters at a decent price.

I'm told that programming this would be a Bear, why?

I could just flip the part and make the blend from both sides but I think setup and cycle speed would be faster if I can do most of it from one side.

Price of the cutter aside, what is the advice on these cutters and this operation?