jprobst

Cast Iron

- Joined

- Aug 22, 2006

- Location

- covina, ca

Need help with machining a part and loading a edrawing to this forum

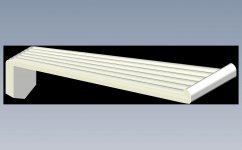

I a question for all of you seasoned programmers. I have these parts to do for a lamp. There are 3 legs per lamp and have 35 lamps to do. They want them done out of cold rolled material because they are going to be plated. I will try to attach a cad drawing but please let me know if it doesnt work. I'm just trying to accomplish the humps. The only way I can see to do this is too srface machine it. Any body have any ideas for a simpler way?

Crap, how do you attach an edrawing?

I a question for all of you seasoned programmers. I have these parts to do for a lamp. There are 3 legs per lamp and have 35 lamps to do. They want them done out of cold rolled material because they are going to be plated. I will try to attach a cad drawing but please let me know if it doesnt work. I'm just trying to accomplish the humps. The only way I can see to do this is too srface machine it. Any body have any ideas for a simpler way?

Crap, how do you attach an edrawing?

Last edited: