Is it a waste of time to use the machine control's tool life management? We keep destroying milling cutter all the time, especially high feed ones, because everybody changes inserts when they think it's about the time. There's no statistical data or anything, just the feeling (+visual cues of course). I'd like to start collecting some data - I already incorporated tool life activation code in our CAM system's post processor - but everybody says it's a waste of time. Despite the ever-increasing pile of broken cutters. I've asked operators to reset the tool life counter when changing inserts so that *only* I can collect data, but that is also too much to ask.

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool life management, a waste of time?

- Thread starter 316head

- Start date

- Replies 24

- Views 12,164

Milland

Diamond

- Joined

- Jul 6, 2006

- Location

- Hillsboro, New Hampshire

Try to get Tonytn36's attention on this post, he's one of the best options for a good answer.

CarbideBob

Diamond

- Joined

- Jan 14, 2007

- Location

- Flushing/Flint, Michigan

IMO, Not a waste of time.

Down time or scrap due to not changing early enough is a waste.

Running a tool to the death in a production environment is usually not good for the pocketbook.

You are on the right path but one has to have faith or proof of when to toss a tool that is still running.

You should not eat up cutter bodies expect for big .... oops, oh-shit days.

.... and also waiting for Tony to describe how his place runs this and feedback from other tooling guys or vendors.

.... and also waiting for Tony to describe how his place runs this and feedback from other tooling guys or vendors.

Is running a tool change hard or to the point of failure profitable?

Does it make sense to change at xxx parts or time when a cutter is still working okay?

Do you pull a tool or inserts early or push until it will not cut and in what type shop is one method better or worse?

Bob

Down time or scrap due to not changing early enough is a waste.

Running a tool to the death in a production environment is usually not good for the pocketbook.

You are on the right path but one has to have faith or proof of when to toss a tool that is still running.

You should not eat up cutter bodies expect for big .... oops, oh-shit days.

.... and also waiting for Tony to describe how his place runs this and feedback from other tooling guys or vendors.

.... and also waiting for Tony to describe how his place runs this and feedback from other tooling guys or vendors.Is running a tool change hard or to the point of failure profitable?

Does it make sense to change at xxx parts or time when a cutter is still working okay?

Do you pull a tool or inserts early or push until it will not cut and in what type shop is one method better or worse?

Bob

Tonytn36

Diamond

- Joined

- Dec 23, 2007

- Location

- Southeastern US

It is not a waste of time. Since you don't have much luck with operators resetting the counters, get a starting point by taking the expected life for your inserts from the mfg data. i.e. cut time. You can calculate, based on your material, cutting conditions and mfg expected life the amount of parts that the tool should live. Use that number initially in the tool life management. Track results. If no more broken tools or quality issues with the parts, then slowly increase the life until something stops you. Your data will tell you where to stop, or back up to. This is not a fix it in a day thing, you need a good data set over time and many sets of inserts.

You must have personnel management policies in place to help you. If they just reset the life counter and don't change the tools then you are wasting your time. You can keep track of insert inventory to ensure they are changing them and if not then you have data to prove they aren't. You also need to track the costs so that you have something for management to see what the cost is of not abiding by the tool life requirement. It doesn't take many blown up cutter bodies and especially the downtime costs to add up to a very significant amount of money.

We go through millions of dollars worth of inserts a year. If you pick them up out of the recycling bin, they all look like they could run longer and that is true, they could. But, you don't know how many more it could run.... could be 1 part, could be 10, could be 30 - it becomes very unpredictable after the established tool life is used up. The measly cost of the insert vs a scrapped part+holder+downtime is not worth the risk to get maybe 5 or 10 more parts out of that insert.

Example:

Insert $7 - 4 usable edges

Part cost = $80

Holder cost = $140

Downtime cost = $400/hr

So say you get 50 parts on an insert edge reliably, 99.9% of the time the tool edge will last 50 parts without issue. It takes 2 min to roll or change the insert and make the minor adjustment. Your cost per edge is ($7/4) + ((400/60)*(2)) = $15.08/50 parts = $0.30/part for that insert edge.

Now you run the tool edge to failure and it breaks on the 60th part. Now you have a broken/damaged holder and a scrap part so now it takes 10 minutes to put in a new holder and dial it in.

Now you have (($7/4)+((400/60)*10)+140+80) = $288.42/60 parts = $4.88/part for that insert edge. Which situation is more profitable?

You must have personnel management policies in place to help you. If they just reset the life counter and don't change the tools then you are wasting your time. You can keep track of insert inventory to ensure they are changing them and if not then you have data to prove they aren't. You also need to track the costs so that you have something for management to see what the cost is of not abiding by the tool life requirement. It doesn't take many blown up cutter bodies and especially the downtime costs to add up to a very significant amount of money.

We go through millions of dollars worth of inserts a year. If you pick them up out of the recycling bin, they all look like they could run longer and that is true, they could. But, you don't know how many more it could run.... could be 1 part, could be 10, could be 30 - it becomes very unpredictable after the established tool life is used up. The measly cost of the insert vs a scrapped part+holder+downtime is not worth the risk to get maybe 5 or 10 more parts out of that insert.

Example:

Insert $7 - 4 usable edges

Part cost = $80

Holder cost = $140

Downtime cost = $400/hr

So say you get 50 parts on an insert edge reliably, 99.9% of the time the tool edge will last 50 parts without issue. It takes 2 min to roll or change the insert and make the minor adjustment. Your cost per edge is ($7/4) + ((400/60)*(2)) = $15.08/50 parts = $0.30/part for that insert edge.

Now you run the tool edge to failure and it breaks on the 60th part. Now you have a broken/damaged holder and a scrap part so now it takes 10 minutes to put in a new holder and dial it in.

Now you have (($7/4)+((400/60)*10)+140+80) = $288.42/60 parts = $4.88/part for that insert edge. Which situation is more profitable?

5 axis Fidia guy

Stainless

- Joined

- Aug 17, 2006

- Location

- Wisconsin

I use it on all my tools, I have a fairly good idea of how long a high feed insert will last on hard material. If I leave for the day it's quite easy just to take a peek at the time left and see if it will last the night run.

In a production environment, I take it right out of the operators' hands. I write a macro program that has a parts counter, automatic tool change based off of the part counter and tool change message. P.M. me with your email address and I will send you a program example (it is a lathe but same principal).

In a production environment, I take it right out of the operators' hands. I write a macro program that has a parts counter, automatic tool change based off of the part counter and tool change message. P.M. me with your email address and I will send you a program example (it is a lathe but same principal).

Adding on to this, I don't know what machine the OP is programming, but Okuma has MacMan that can output data. You can see download that file and look at that. Impossible for the operator to change.

ewlsey

Diamond

- Joined

- Jul 14, 2009

- Location

- Peoria, IL

Adding on to this, I don't know what machine the OP is programming, but Okuma has MacMan that can output data. You can see download that file and look at that. Impossible for the operator to change.

The operator can delete it...

Okuma has a decent tool life management in the newer controls. But, it can't count the number of holes for drills. That's just stupid. I asked the applications people. Crickets.

Just my opinion, but it depends on the work you do. If you run a production job on a regular basis and you can collect tool life data, it's good. If you run the same materials in the same setups on a regular basis, it's good.

If you run a job shop with a lot of short runs and odd setups, it's not really helpful. I used to work in a shop where we ran a lot of really complicated parts at very low volumes. So, we might have a casting with 6 different sizes of spool valve ports each requiring 2 or 3 special ground form tools. Then we might make less than 50 parts a year. It could take a decade to get to a point where the tools needed to be sharpened. But, tools that were used in other parts, like face mills, end mills, common drills, etc were easy to implement.

I wasn't aware of that. I don't utilize MacMan all that often.The operator can delete it...

DMF_TomB

Diamond

- Joined

- Dec 13, 2008

- Location

- Rochester, NY, USA

.Is it a waste of time to use the machine control's tool life management? We keep destroying milling cutter all the time, especially high feed ones, because everybody changes inserts when they think it's about the time. There's no statistical data or anything, just the feeling (+visual cues of course). I'd like to start collecting some data - I already incorporated tool life activation code in our CAM system's post processor - but everybody says it's a waste of time. Despite the ever-increasing pile of broken cutters. I've asked operators to reset the tool life counter when changing inserts so that *only* I can collect data, but that is also too much to ask.

.

1) most shops have a safety factor so after say 60 minutes the tool will not go through tool changing allowing operator to inspect tool and add time if it looks ok. quite common to add time but many times tool looks bad and no time is added.

.

2) standard on long running ops to send tool back to tool changer and call it back out if tool expired it will call next tool with same tool number instead of expired one. obviously can have 2 or 3 tools on same tool number in tool magazine.

.

3) cause some parts vibrate more than others obviously at same feeds and speeds you might get less than 30% the tool life of a rigid non chattering part. quite common to add M0 after a op that has tool life problems to inspect cutter and see if still ok. if not replace cutter and redo op. many times i have adjusted feeds and speeds to increase tool life back to more normal levels. often its as simple as listening to noise level and adjusting at whats louder than normal.

.

4) many a time i have increased feeds and speeds til the tool life shortens to 60 minutes and stopped there to maintain reasonable tool life. when you start at 16 ipm feed and get up to 50 ipm feed obviously there is little reason to keep going so slow

.

5) tool life is never exactly predictable cause metal can be harder than normal. quite common to adjust feeds and speeds and do 10 parts and then have problems on a part harder than normal or full of hard spots.

.

6) on high precision finish cuts obviously tool life will predict tool dulling and when problems with maintaining tolerances will occur. quite common for end mills to get tapered or non parallel from wear and facemilling to get lap and waviness problems

.

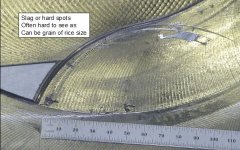

7) i use computerized tool system. if a drill has a damaged flute as shown and is drilling .040" oversize holes i can look up time and date it was in machine spindle and determine parts possibly effected. drill shown had 2 minutes used. a lot of bad parts made in 45 minutes before tool would be expired and looked at. even worse would be if tool have 300 minute tool life time. expired tools force looking at tool. doesnt mean it has to be changed only looked at then a decision is made if changing is needed

.

8) i use excel file on tool feeds and speeds and record any sudden tool failures. sometimes tool is just going too fast and sometimes it is just the flimsy part vibrating causing the problems

Attachments

hello 316 head  what kind of data data would you like to analyze, and how are you going to get the values ?

what kind of data data would you like to analyze, and how are you going to get the values ?

you need the operator to reset the counters ? maybe it seems normal, but it is too invasive : newer operators have too many things on their heads, while others will simply change the inserts as they feel and wont give you feedback from various reasons, but mainly because you can not convince them that there is a benefit sorry, but this is true ...

sorry, but this is true ...

just imagine that you allready have the values / whats next ? so you tuned the CAM, and also made a request to the operators to clear the timers; whats next ?

try cutting specs auto-tuning, based on effort values; something like adaptive machining; use non invasive data loging; log user inputs, etc

at this stage you wish to colect data; this is the begining, but what is your goal ? the more things you will desire, you will need a more capable control, with custom applications on it, running without increasing the system load and the cycle time, and in the end, when you will know things, only then you may decide to stop using them

what kind of data data would you like to analyze, and how are you going to get the values ?

what kind of data data would you like to analyze, and how are you going to get the values ?you need the operator to reset the counters ? maybe it seems normal, but it is too invasive : newer operators have too many things on their heads, while others will simply change the inserts as they feel and wont give you feedback from various reasons, but mainly because you can not convince them that there is a benefit

sorry, but this is true ...

sorry, but this is true ...just imagine that you allready have the values / whats next ? so you tuned the CAM, and also made a request to the operators to clear the timers; whats next ?

try cutting specs auto-tuning, based on effort values; something like adaptive machining; use non invasive data loging; log user inputs, etc

at this stage you wish to colect data; this is the begining, but what is your goal ? the more things you will desire, you will need a more capable control, with custom applications on it, running without increasing the system load and the cycle time, and in the end, when you will know things, only then you may decide to stop using them

mhajicek

Diamond

- Joined

- May 11, 2017

- Location

- Maple Grove, MN, USA

Even a Haas has tool life management these days. If you have a spare ATC pocket put in a second copy of the tool and make a guess about cutter life based on how many inserts they've been going through. Tweak from there.

Jashley73

Titanium

- Joined

- Jan 24, 2013

- Location

- Louisville, KY

In a production setting, tool life monitoring is a must. If you don't have controlled tool life, then your tool costs per part are out of control, tool-change labor & downtime is out of control, and it eats into the bottom line. In a truly competitive production environment, that can have significant financial impact.

Tony's post is spot on. I have some experience on a much smaller scale than his, but his post is still 100% spot on.

If downtime to exchange tools is considered a "nuisance" then consider buying duplicate tools. The operator simply removes the dull tool, loads a fresh tool, and the machine keeps on running. The dull tools can be kept for evaluation, or changed by the operator while the machine is running. This can seem like an excessive cost at first, but not hard to justify when production runs smoother, and scrap part & tooling costs fall...

Tony's post is spot on. I have some experience on a much smaller scale than his, but his post is still 100% spot on.

If downtime to exchange tools is considered a "nuisance" then consider buying duplicate tools. The operator simply removes the dull tool, loads a fresh tool, and the machine keeps on running. The dull tools can be kept for evaluation, or changed by the operator while the machine is running. This can seem like an excessive cost at first, but not hard to justify when production runs smoother, and scrap part & tooling costs fall...

Matt_Maguire

Stainless

- Joined

- Oct 17, 2011

- Location

- West-Central Illinois, USA

Is it a waste of time to use the machine control's tool life management? We keep destroying milling cutter all the time, especially high feed ones, because everybody changes inserts when they think it's about the time. There's no statistical data or anything, just the feeling (+visual cues of course). I'd like to start collecting some data - I already incorporated tool life activation code in our CAM system's post processor - but everybody says it's a waste of time. Despite the ever-increasing pile of broken cutters. I've asked operators to reset the tool life counter when changing inserts so that *only* I can collect data, but that is also too much to ask.

Tracking tool wear for predicting change out is very useful, further it goes back to “stone age” machining before carbide got here. The wear land and/or crater was measured & at a certain (agreed to) point, the tool was sharpened/changed.

Respectable operations tracking part cost vs tooling got as good as $0.001 for stamping per part, $0.01 for high production machining and $0.1 for low production or castings by the 1950’s. Actually got that good with most of the other cost inputs as well.

You have to get the operators to drink the kool-aid and believe any extra effort by them to help predict the future is worth that effort. Mileage really varies on this with skilled people on trusting this & it’s a shame.

Good luck,

Matt

Tony Quiring

Titanium

- Joined

- Nov 5, 2008

- Location

- Madera county california usa

Just a simple statement....

A carbide insert takes seconds to change and insert cost not much.

Scrap is expensive in waste.

Simple math can be used with manufacturer data sheets to estimate tool life and inspection of tool at or near that point can confirm calculations to adjust time of use.

Cost of tooling is included in production cost so simple math determines a given amount of "consumables" to use.

If a multiple tool machine is in use and possible duplicates of same tool or process to allow cutter change while a given holder is not in use to reduce down time.

Makes zero sense to push the life of inserts past expected life when cost of failure is much higher than cost of inserting a new unsert.

Replacing before broken is a " point of sale " while recovery from breakage is a "cost of production"

Sent from my SAMSUNG-SGH-I337Z using Tapatalk

A carbide insert takes seconds to change and insert cost not much.

Scrap is expensive in waste.

Simple math can be used with manufacturer data sheets to estimate tool life and inspection of tool at or near that point can confirm calculations to adjust time of use.

Cost of tooling is included in production cost so simple math determines a given amount of "consumables" to use.

If a multiple tool machine is in use and possible duplicates of same tool or process to allow cutter change while a given holder is not in use to reduce down time.

Makes zero sense to push the life of inserts past expected life when cost of failure is much higher than cost of inserting a new unsert.

Replacing before broken is a " point of sale " while recovery from breakage is a "cost of production"

Sent from my SAMSUNG-SGH-I337Z using Tapatalk

implmex

Diamond

- Joined

- Jun 23, 2002

- Location

- Vancouver BC Canada

Hi All:

I don't see any comments by the OP about what kind of work he is doing.

If it's production, all of what you guys have commented on makes perfect sense; but if he's doing low volume jobbing or repair work it's kind of pointless; don't you think?.

Another point brought up only by ewlsey so far; a lot depends on the consistency of the processing; if it's all over the map in other domains, there's not much point in controlling only this one part of it.

So as one part of a complete production plan...yes, by all means.

As a standalone magic bullet to solve a persistent tool breakage problem...maybe not so much.

Cheers

Marcus

Implant Mechanix • Design & Innovation > HOME

www.vancouverwireedm.com

I don't see any comments by the OP about what kind of work he is doing.

If it's production, all of what you guys have commented on makes perfect sense; but if he's doing low volume jobbing or repair work it's kind of pointless; don't you think?.

Another point brought up only by ewlsey so far; a lot depends on the consistency of the processing; if it's all over the map in other domains, there's not much point in controlling only this one part of it.

So as one part of a complete production plan...yes, by all means.

As a standalone magic bullet to solve a persistent tool breakage problem...maybe not so much.

Cheers

Marcus

Implant Mechanix • Design & Innovation > HOME

www.vancouverwireedm.com

DMF_TomB

Diamond

- Joined

- Dec 13, 2008

- Location

- Rochester, NY, USA

much depends on material being machined. often when dealing with cast iron with random hardspots tool life can be hard to predict.

.

you hit big hardspot tool can be badly damaged in less than 2 minutes. you can slow things down to a less than 30% highest possible and still wipe out inserts within seconds of hitting bigger hard spots

.

tool life is mostly a tool for reminding operator to look at the tool periodically, if it looks ok then adding time is normally not a problem. many a mill had corners broken off and was not even noticed til operator looked at the tool

.

you hit big hardspot tool can be badly damaged in less than 2 minutes. you can slow things down to a less than 30% highest possible and still wipe out inserts within seconds of hitting bigger hard spots

.

tool life is mostly a tool for reminding operator to look at the tool periodically, if it looks ok then adding time is normally not a problem. many a mill had corners broken off and was not even noticed til operator looked at the tool

Attachments

lspotts38

Aluminum

- Joined

- Mar 7, 2012

- Location

- Northcentral Pennsylvania

The operator can delete it...

Okuma has a decent tool life management in the newer controls. But, it can't count the number of holes for drills. That's just stupid. I asked the applications people. Crickets.

I'm more familiar with the current P300 controls, so don't hold me to it on the older ones, but they do have the capability of tracking hole count. They give you several options for tool life monitoring, I use two of them, cut time and "number of work" or something similar. Number of work gives you the ability to advance the tool life count by a number, so after the tool change you give it a TLMNCN Q[whatever] (don't quote me on the variable, I'll check tomorrow) and it advances the count by the Q value.

I don't think Macman would be very easy to work around. There is a "gather logs" function that generates log files, and Okuma can open the files and give a report of keystrokes, alarms and operation history. Dunno where that data comes from, but I have looked in MacMan for history of "things", wasn't there, and Okuma could find it in those log files after I gave them to them.

Fadriver

Aluminum

- Joined

- Apr 24, 2011

- Location

- los angels ca.

Pretty useless for a one guy/operator per machine shop, but can be useful for shifts e.g. multiple operators.

We don;t use Tmgt here but perhaps we should

Unless you running one operator in different units

is a problem, I ran machining cell before and 2 operators manned 4 machines and didn't had problems

because machine proximity, insert fail change new one, reset tool number and no scrap, I would say training workers is key,you hear when a insert is going to fail,unless you run automatic loaders i thinks is a big problem.

I think boils down on worker training,teamwork,my boss owner used to tell me,workers can make you tons of money but they also can break you up.

Similar threads

- Replies

- 5

- Views

- 253

- Replies

- 3

- Views

- 155

- Replies

- 2

- Views

- 626