peninsula

Aluminum

- Joined

- Mar 15, 2012

- Location

- Florida USA

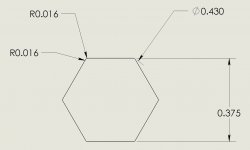

I have a buddy who needs to mill a 3/8 hex where the corners blend into a .430 diameter with a .016 radius. I was wondering if anyone had a sample of the code on this. I have seen it done in videos but thats about it. The control will be a fanuc 21