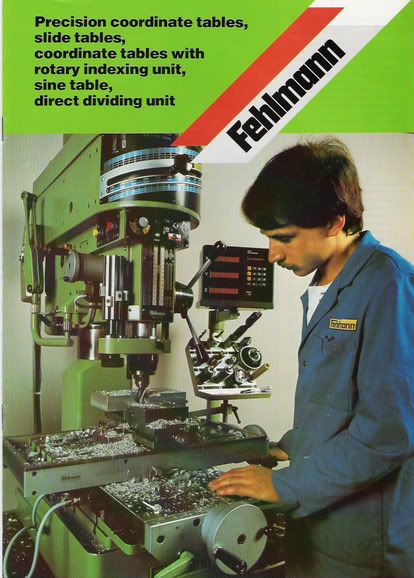

Finally got my Swiss baby cleaned up enough for some photos. Still need to take some Nevrdull to the column, and a few other details. Cute, huh ?

Note the pushbuttons at the end of each handwheel spoke...push in for power feed, push again to stop feed. Power column with raise with reseatable stops, quick change spindle..just raise it and tool pops out, tapping functions.

Fit and finish as good as it gets. One example, note how the Heidenhain scales are competely integrated into the table, rather than bolted on. Quill movement is absolute perfection...smooth as I've ever felt with perfect counterbalance and yet no perceptable play. A Moore jig borer quill, which is excellent, seems stiff and less balanced in comparison.

Sort of a tabletop jig borer that will also mill, drill and tap...with lightning fast tool changes.

Note the pushbuttons at the end of each handwheel spoke...push in for power feed, push again to stop feed. Power column with raise with reseatable stops, quick change spindle..just raise it and tool pops out, tapping functions.

Fit and finish as good as it gets. One example, note how the Heidenhain scales are competely integrated into the table, rather than bolted on. Quill movement is absolute perfection...smooth as I've ever felt with perfect counterbalance and yet no perceptable play. A Moore jig borer quill, which is excellent, seems stiff and less balanced in comparison.

Sort of a tabletop jig borer that will also mill, drill and tap...with lightning fast tool changes.

)

)