traditional-tools

Diamond

- Joined

- Aug 10, 2007

- Location

- West Coast

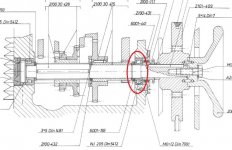

Ok, I was able to drain the feed gearbox on the operator side of the machine (lower one), filled it with kerosene and ran it for about 5-10 minutes feeding back and forth. flushed that and filled it with oil and all is well.

On the other side is the speed gearbox (upper), and the large allen screw can be undone and a rod pulls out with a hole to allow the oil to drain...but for the ilfe of me, the oil doesn't want to go in the fill port. There are two bolts, and neither one wants to allow oil into the tank very fast. Is there some secret? Seems I'm spilling more down the size of the machine than is going inside...at this rate I don't think I'll have enough oil with a gallon, so I stopped and thought I would ask.

Does this just require a lot of patience ? (and a lot of oil ?)

Cheers,

Alan

On the other side is the speed gearbox (upper), and the large allen screw can be undone and a rod pulls out with a hole to allow the oil to drain...but for the ilfe of me, the oil doesn't want to go in the fill port. There are two bolts, and neither one wants to allow oil into the tank very fast. Is there some secret? Seems I'm spilling more down the size of the machine than is going inside...at this rate I don't think I'll have enough oil with a gallon, so I stopped and thought I would ask.

Does this just require a lot of patience ? (and a lot of oil ?)

Cheers,

Alan