Brian_Petersen

Plastic

- Joined

- Apr 20, 2017

Hi,

I have some questions regarding lubricants for my most recent investment, a MAHO MH 600:

(Some members call it an old mule! )

)

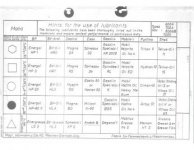

1. Recommended Main Gear oil is Mobil Vactra Oil Heavy Medium. Is it OK to use Total CARTER EP68?

2. Recommended H-drive oil is Mobil Velocite Oil No. 4. What would you choose from Total?

3. Recommended grease is Mobilux grease No. 2. Can I use AeroShell Grease 5 or 14 instead?

4. Mobil Velocite Oil ED seems to have be been discontinued and I cannot find any datasheet. Recommendations?

5. Is Total EQUIVIS ZS32 good for any kind of machine related lubrication?

6. Suitable plain bearing lubricant? My spindle has a tapered bronze and journal bearing.

I can get Total products from my work through our local supplier, so it's the preferred brand.

Thanks,

Brian

I have some questions regarding lubricants for my most recent investment, a MAHO MH 600:

(Some members call it an old mule!

)

)1. Recommended Main Gear oil is Mobil Vactra Oil Heavy Medium. Is it OK to use Total CARTER EP68?

2. Recommended H-drive oil is Mobil Velocite Oil No. 4. What would you choose from Total?

3. Recommended grease is Mobilux grease No. 2. Can I use AeroShell Grease 5 or 14 instead?

4. Mobil Velocite Oil ED seems to have be been discontinued and I cannot find any datasheet. Recommendations?

5. Is Total EQUIVIS ZS32 good for any kind of machine related lubrication?

6. Suitable plain bearing lubricant? My spindle has a tapered bronze and journal bearing.

I can get Total products from my work through our local supplier, so it's the preferred brand.

Thanks,

Brian

with good help from a pneumatic brake bleeder. My worst experience was the oil chamber with three wicks for lubricating the rapid traverse gears on the X-axis. The chamber was just packed with grease and it had nowhere to go! I should have taken a picture before the operation, but now it is cleaned up. I made some new wicks made from an old tea towel (and adjusted the length and cut off the fuzzy threads afterwards)

with good help from a pneumatic brake bleeder. My worst experience was the oil chamber with three wicks for lubricating the rapid traverse gears on the X-axis. The chamber was just packed with grease and it had nowhere to go! I should have taken a picture before the operation, but now it is cleaned up. I made some new wicks made from an old tea towel (and adjusted the length and cut off the fuzzy threads afterwards)