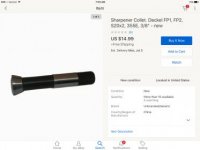

I found these on eBay. I wonder if they will fit

Yes, they will, if you have the sleeve as Dan mentioned. The sleeve will allow you to use these single-lip style collets, which suck IMO, as the sleeve gets stuck in the spindle easy. In that regard, the original MK4 taper with S20x2 thread on them work the best between spindle collets and stick down less to provide the most headroom on your Z axis. Same with the single lip collets but you need to deal with the sleeve. One note, be careful on the Alexander style collets on ebay.uk, I'm not sure they will work in a Deckel/Maho, they look slightly different.

The collet chuck is not a bad solution (I have 2, ER40 and ER32 both of which I bought from Singer). Providing the same tooling works on your Maho that works on the Deckel, you can get the collet chuck from Singer with the S20x2 thread on it (about $100 plus shipping). Otherwise you'll need to adapt either an M16 or 5/8-11. I also have plugs which are S20x2->5/8-11 and you can deal with those on an inch machine by tapping/threading 5/8-11 on the tool end and thread it in with loctite. You still need to cut the taper down, most tools are only hard for the thickness of the surface, but all vary. Tapping that crap is not as easy as one would hope, in my experience. I have a Wholhaupter I've done it to on an MT4 shank. Single point may be easier on the lathe.

Lastly, you could fabricate a new draw bar to replace the captive draw bar, but I don't know if that would work. There would need to be enough room inside the spindle to shorten it up, and my guess is there's not enough room.

Good luck on your decision, you have a few choices, non of them are plug and play, however.

Cheers,

Alan