texasgeartrain

Titanium

- Joined

- Feb 23, 2016

- Location

- Houston, TX

Not sure if this is the correct forum section, but it is the only I see for Euro type mills. This is a continuation of a a conversation started under the Cincinnati, K & T, USA machines forum section where we were discussing milling machine comparisons here:

http://www.practicalmachinist.com/v...son-im-rookie-345555-post3119491/#post3119491

As the likelihood is high that I'll be dragging this machine home, I'd thought I'd start a new thread to expand the topic on this machine, and hopefully get some feed back.

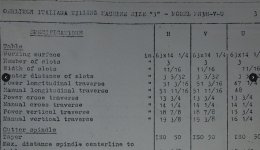

This Oerlikon is located near to me. I went to see it first hand today. I have worked out a very reasonable price, should I decide to buy it. My time was limited today. I had about an hour. I looked it over the best I could, and got as much information as possible.

I only had an hour. . . I really could have used the whole day. The owner offered to let me power it up, and operate it. I declined for now, because the machine has not been operated in years. Someone coated ways with grease years ago. I didn't want to drag dirt and debris into it without cleaning first. Also I'd want to change the fluids before operating. Anyway, I'll lay out what pics and info I have so far.

http://www.practicalmachinist.com/v...son-im-rookie-345555-post3119491/#post3119491

As the likelihood is high that I'll be dragging this machine home, I'd thought I'd start a new thread to expand the topic on this machine, and hopefully get some feed back.

This Oerlikon is located near to me. I went to see it first hand today. I have worked out a very reasonable price, should I decide to buy it. My time was limited today. I had about an hour. I looked it over the best I could, and got as much information as possible.

I only had an hour. . . I really could have used the whole day. The owner offered to let me power it up, and operate it. I declined for now, because the machine has not been operated in years. Someone coated ways with grease years ago. I didn't want to drag dirt and debris into it without cleaning first. Also I'd want to change the fluids before operating. Anyway, I'll lay out what pics and info I have so far.