How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Charmilles Threading Jet

- Thread starter CMD1992

- Start date

- Replies 5

- Views 4,313

- Status

- Not open for further replies.

KilrB

Stainless

- Joined

- Feb 18, 2007

- Location

- Angleton, Texas

Got a charmilles cut 400, have a problem with the threading jet instead of a straight jet it just sprays water meaning that the wire doesnt thread from any height's above 2" is there a way to adjust the jet?

Sounds like you have some trash stuck in your threading nozzle.

That or you've broken it, which is easy if it's one of the all ceramic type instead of the ones with the ceramic insert.

Remove the upper nozzle, then the upper nut.

Be careful not to drop the guide, extension pipe, and nozzle out when you do.

Turn the threading jet on/off a couple times to blow any trash out.

Now remove the guide, extension pipe, and nozzle from the upper nut and clean the channels in the nozzle.

Check that the ceramic in the nozzle isn't cracked.

If you have a microscope, check your guide too.

Replace them if they are cracked or broken.

Reassemble and check the jet.

During reassembly take extra care that the guide remains seated in the nozzle and the extension tube is on straight.

If it's good do a guide adjustment and you are ready to go.

Last edited:

charmilles89

Plastic

- Joined

- Mar 5, 2019

- Location

- Grand Rapids MICHIGAN, UNITED STATES

Adding a nice filter to all the small fine water circuits (threading,wetting,and aspiration)Sounds like you have some trash stuck in your threading nozzle.

That or you've broken it, which is easy if it's one of the all ceramic type instead of the ones with the ceramic insert.

Remove the upper nozzle, then the upper nut.

Be careful not to drop the guide, extension pipe, and nozzle out when you do.

Turn the threading jet on/off a couple times to blow any trash out.

Now remove the guide, extension pipe, and nozzle from the upper nut and clean the channels in the nozzle.

Check that the ceramic in the nozzle isn't cracked.

If you have a microscope, check your guide too.

Replace them if they are cracked or broken.

Reassemble and check the jet.

During reassembly take extra care that the guide remains seated in the nozzle and the extension tube is on straight.

If it's good do a guide adjustment and you are ready to go.

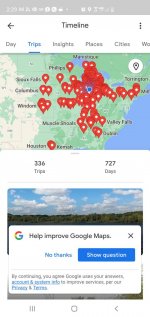

View attachment 173815

Will make your problems stay away for. long time

Over time in the older edms the manifold and valve that are placed after main filter start to slime up.

If the machine gets turn off and slime dries, it falls off, and gets clogged somewhere downstream.

So often we will replace the lines and fitting to the head.

If that is not a option, We run a light cleaning acid thru tube and blow them out.

We do this everytime we rebuild a edm. machine here at Great Lakes Wire Repair dot com

Machine threading flawless for a long time. each machine often we will test the cut/thread cycle 50 to 100 times in a row to ensure reliability.

Also we can provide the rethreading modules on the charmilles,these are very prone to leakage and water getting it the motor and microswitch we sell them for about 1100.00

I think gf gets over 2500 for them

Sent from my SM-G975U using Tapatalk

charmilles89

Plastic

- Joined

- Mar 5, 2019

- Location

- Grand Rapids MICHIGAN, UNITED STATES

Sorry I thought you said older 400 my badGot a charmilles cut 400, have a problem with the threading jet instead of a straight jet it just sprays water meaning that the wire doesnt thread from any height's above 2" is there a way to adjust the jet?

But still the filter is not a bad option it can't hurt any thing

ALWAYS have a new thread jet on hand.

Make sure you get the right size hole according to the taper angles your cutting

Big taper big hole

If when you put it togather and it don't hit the guide with perfect cone spray at UV 0,0 it's fucked

Don't attempt to comp it

Here's a easy solution from novotec we can get you 10% off if you order with us

Sent from my SM-G975U using Tapatalk

plastikdreams

Diamond

- Joined

- May 31, 2011

- Location

- upstate nj

Sorry I thought you said older 400 my bad

But still the filter is not a bad option it can't hurt any thing

ALWAYS have a new thread jet on hand.

Make sure you get the right size hole according to the taper angles your cutting

Big taper big hole

If when you put it togather and it don't hit the guide with perfect cone spray at UV 0,0 it's fucked

Don't attempt to comp it

Here's a easy solution from novotec we can get you 10% off if you order with us

Sent from my SM-G975U using Tapatalk

I didn't know east Lansing was a place in the aaland islands...hmm

charmilles89

Plastic

- Joined

- Mar 5, 2019

- Location

- Grand Rapids MICHIGAN, UNITED STATES

Dude your not contributing in any wayI didn't know east Lansing was a place in the aaland islands...hmm

I'm sorry my location is wrong

Get over it dude

I'm a little busy fixing machines and NOT Trolling like you are.

Been at the tool shows making connections with major people

Learning and educating myself

So sorry my location is constantly a problem for You Guy!

Talk about machining or don't say nothing at all is how I feel about this place

Sent from my SM-G975U using Tapatalk

All I'm going to say was that you were reported for shady business practices...I'll leave it as that.

- Status

- Not open for further replies.

Similar threads

- Replies

- 5

- Views

- 737

- Replies

- 4

- Views

- 688