Mmtz

Aluminum

- Joined

- Apr 24, 2012

- Location

- San Carlos, MX

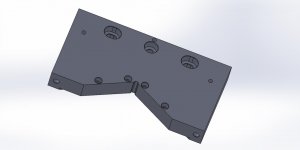

Like the title says it, I'm looking into some wire EDM tooling from this company, specifically this:

Wire EDM Rails

I know I could make them myself but I don't have the time or even a grinder on this shop.

So any recommendations? Any other small companies selling this kind of tooling?

There is a guy on Ebay selling the same kind of fixture but I had a really bad result on dealing with him and I just need something now! Looks like at least these 2 guys and another one I called don't have anything in stock and everything gets made to order.

Had the other guy ship an incomplete set of clamps, only shipped a partial were the items were out the shelf bolts and what looks like unfinished clamps, as in not ground/cleaned clamps and at least one of the sizes don't look to have been heat treated at all as per the item description on the ad.

As received

As received

On the ad

On the ad

I know different Heat treat temps would make them look different but I just don't see any signs of the large ones being treated.

I guess it doesn't surprise me when even the clamp set that came with the machine had hex posts come in drill but not tapped.

So anyways, getting off my rant mode, Does anyone have any recommendations besides the obvious?

Thanks in advance!

MMtz

Wire EDM Rails

I know I could make them myself but I don't have the time or even a grinder on this shop.

So any recommendations? Any other small companies selling this kind of tooling?

There is a guy on Ebay selling the same kind of fixture but I had a really bad result on dealing with him and I just need something now! Looks like at least these 2 guys and another one I called don't have anything in stock and everything gets made to order.

Had the other guy ship an incomplete set of clamps, only shipped a partial were the items were out the shelf bolts and what looks like unfinished clamps, as in not ground/cleaned clamps and at least one of the sizes don't look to have been heat treated at all as per the item description on the ad.

As received

As received On the ad

On the adI know different Heat treat temps would make them look different but I just don't see any signs of the large ones being treated.

I guess it doesn't surprise me when even the clamp set that came with the machine had hex posts come in drill but not tapped.

So anyways, getting off my rant mode, Does anyone have any recommendations besides the obvious?

Thanks in advance!

MMtz

.

. . I'm now a happy camper and at least the machine is running smoothly and looks like we'll be fine for a while.

. I'm now a happy camper and at least the machine is running smoothly and looks like we'll be fine for a while.