vanguard machine

Stainless

- Joined

- Dec 20, 2011

- Location

- Charleston and NYC

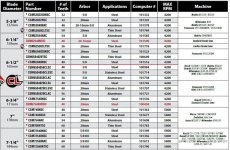

anyone have any recommendations on a better blade for these things than the Milwaukee 8" 42 tooth one or the home despot Freud version?

doing a seemingly simple field job for a customer, busting some .25" mild plate down from 98" x 20' to 90" x 20' so they can fit them into a container.

dead simple, problem is we've been through two blades already and only cut 3 pieces with 10 more to go.

obviously this isn't very economical at almost $70 per blade.

i am taking my time, not forcing the saw, clearing the chips out of the guard every 6' or so and giving the saw a 10 minute break every 10 minutes or so.

i guess worst case i can drag the portable miller plasma torch over there but then i have to fiddle-fuck around with changing 220 twist lock ends and getting the air dry enough with a small portable compressor.

and i'm just not good enough with the gas ax to trust doing them that way.

so, is there a better blade that will give me some life?

thanks gents

doing a seemingly simple field job for a customer, busting some .25" mild plate down from 98" x 20' to 90" x 20' so they can fit them into a container.

dead simple, problem is we've been through two blades already and only cut 3 pieces with 10 more to go.

obviously this isn't very economical at almost $70 per blade.

i am taking my time, not forcing the saw, clearing the chips out of the guard every 6' or so and giving the saw a 10 minute break every 10 minutes or so.

i guess worst case i can drag the portable miller plasma torch over there but then i have to fiddle-fuck around with changing 220 twist lock ends and getting the air dry enough with a small portable compressor.

and i'm just not good enough with the gas ax to trust doing them that way.

so, is there a better blade that will give me some life?

thanks gents

) if you aren't feeding the saw hard enough, causing the blade to rub and generate both heat and rapid wear

) if you aren't feeding the saw hard enough, causing the blade to rub and generate both heat and rapid wear