alpha1

Aluminum

- Joined

- Jan 28, 2005

- Location

- Windsor, ON

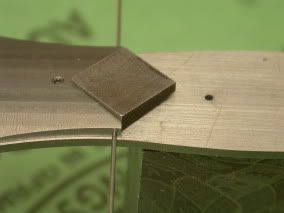

I encountered a problem recently in drilling small holes, drill size is #76 (0.020" diameter),

depth is 0.075", material stainless steel 316,

I used cutting oil, tried several rpm on my precision drilling machine but drills keeps breaking , any suggestion to solve the problem

, any suggestion to solve the problem

alpha1

depth is 0.075", material stainless steel 316,

I used cutting oil, tried several rpm on my precision drilling machine but drills keeps breaking

alpha1

,

,