I received an interesting book from Lindsay called "Metal Spinning." There is a machine shop in town that advertises metal spinning. This is a process for forming a spinning metal disk around a metal or wood form "chuck" by pressing on it with blunt tools. I don't see much on metal spinning in the HSM literature or on this forum. Is spinning still done in HSM ? Is there a source for spinning tools and lathe toolrests ?

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Metal Spinning on Lathe ?

- Thread starter Nait

- Start date

- Replies 12

- Views 9,288

Rotate

Aluminum

- Joined

- Feb 5, 2002

- Location

- Toronto, Ontario, Canada

Yes there are many people still plying this trade. I saw some beautiful things which were made of copper at a local craft show using this technique. As for the tools, I think you can fashion them yourself. Check some textbook on this topic and you'll see different toolrest designs. The one that I like has two rows of holes in which the tools can indexed. There was a website where a guy was spinning perfectly shaped copper or aluminum balls for his tesla coil. Unfortunately I didn't bookmark it so I don't have the url. Good luck.

Albert

Albert

As normally metal spinning performed by hand, but using metal spinning machinery such as a lathe is to achieve good metal spinning results. This method used in industrial and personal machine shops. Metal spinning employs a rotating metal disc to shape a work piece by causing the metal to flow into a predetermined shape. Mostly this process frequently used to create rounded metal parts and products.

Jon Bohlander

Stainless

- Joined

- Apr 22, 2003

- Location

- Topeka KS

I have played around with spinning a little. It's fascinating you can see/feel the metal flow and then it wrinkles or tears.

I got where I was doing OK with 3003 h13 aluminum with simple shapes. OK being less than 50% scrap.

I got where I was doing OK with 3003 h13 aluminum with simple shapes. OK being less than 50% scrap. Steel kicked my butt. There is some real skill required to be good at it.

Steel kicked my butt. There is some real skill required to be good at it.

There isn't a lot of info out there for the hobbyist. I read the Art of Metal Spinning and watched some Youtube videos.

http://www.amazon.com/The-Art-Metal...qid=1352938400&sr=8-3&keywords=metal+spinning

the art of metal spinning - YouTube

: Metal Spinning - Axel Fan Baseplate Spinning - YouTube

: Metal Spinning - Axel Fan Baseplate Spinning - YouTube

Metal Spinning 1250mm Dome Spinning Part 5 - YouTube

good explanations: Turkish Metal Spinning with John Akkus - YouTube

CNC spinning: http://www.youtube.com/watch?v=ggqwf2hAuao

I got where I was doing OK with 3003 h13 aluminum with simple shapes. OK being less than 50% scrap.

I got where I was doing OK with 3003 h13 aluminum with simple shapes. OK being less than 50% scrap. Steel kicked my butt. There is some real skill required to be good at it.

Steel kicked my butt. There is some real skill required to be good at it.There isn't a lot of info out there for the hobbyist. I read the Art of Metal Spinning and watched some Youtube videos.

http://www.amazon.com/The-Art-Metal...qid=1352938400&sr=8-3&keywords=metal+spinning

the art of metal spinning - YouTube

: Metal Spinning - Axel Fan Baseplate Spinning - YouTube

: Metal Spinning - Axel Fan Baseplate Spinning - YouTubeMetal Spinning 1250mm Dome Spinning Part 5 - YouTube

good explanations: Turkish Metal Spinning with John Akkus - YouTube

CNC spinning: http://www.youtube.com/watch?v=ggqwf2hAuao

Putch

Hot Rolled

- Joined

- Nov 15, 2011

- Location

- Butler, PA

believe it or not, there are some great forces applied to the lathe by the spinning process. There are dedicated spinning lathes you can buy, not sure on how common they are but there's not much to them. I don't think you would want to use an engine lathe for spinning, it pretty much trashes them from what I understand.

PeteM

Diamond

- Joined

- Jan 15, 2002

- Location

- West Coast, USA

While significant forces are involved -- it is my understanding that the bearings of most any decent lathe should be able to handle metal spinning, within it's swing range. You'll have to rig up a spinning rest and figure out a proper tailstock center (needs more clearance).

FWIW, many of the old school type woodworking lathes (Delta, Powermatic, etc.; and with mid grade bearings) had optional attachments and tools for metal spinning.

FWIW, many of the old school type woodworking lathes (Delta, Powermatic, etc.; and with mid grade bearings) had optional attachments and tools for metal spinning.

cash register

Aluminum

- Joined

- Jun 30, 2010

- Location

- Menomonie WI

Oliver Lathes I think had spinning options/tools available.

Jon Bohlander

Stainless

- Joined

- Apr 22, 2003

- Location

- Topeka KS

I wouldn't do any heavy spinning on an engine lathe. I've used .040" 3003 H13 aluminum which doesn't take serious forces. I tried 20 gauge steel and it was a no go on my lathe that dare not speak it's name.

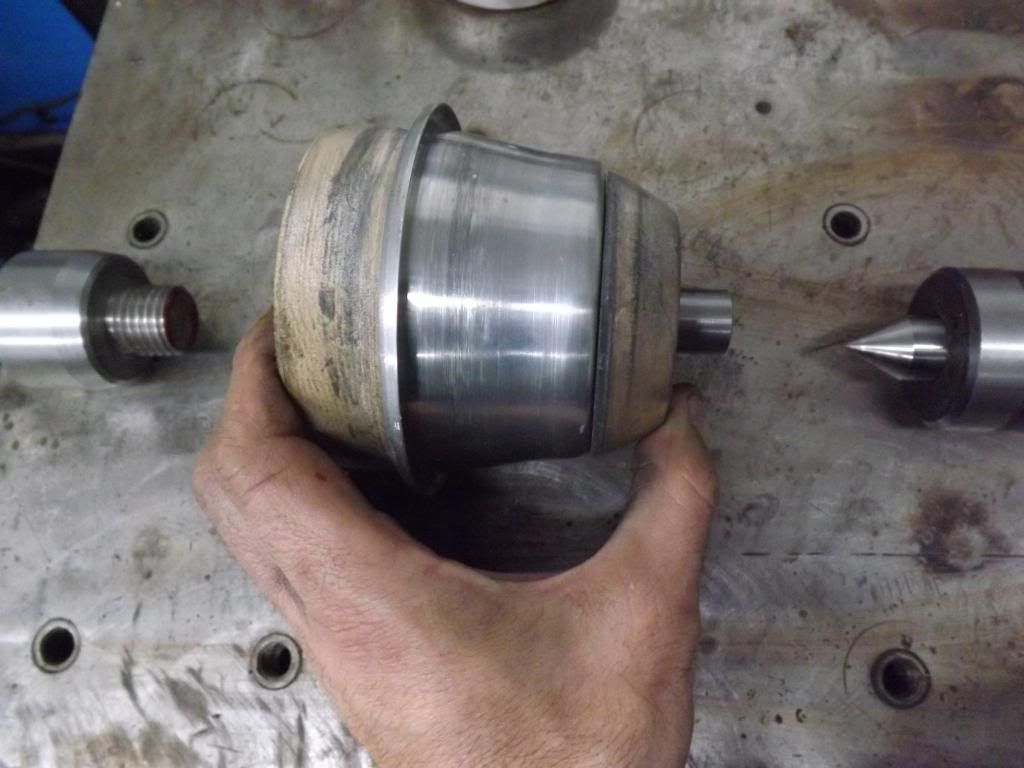

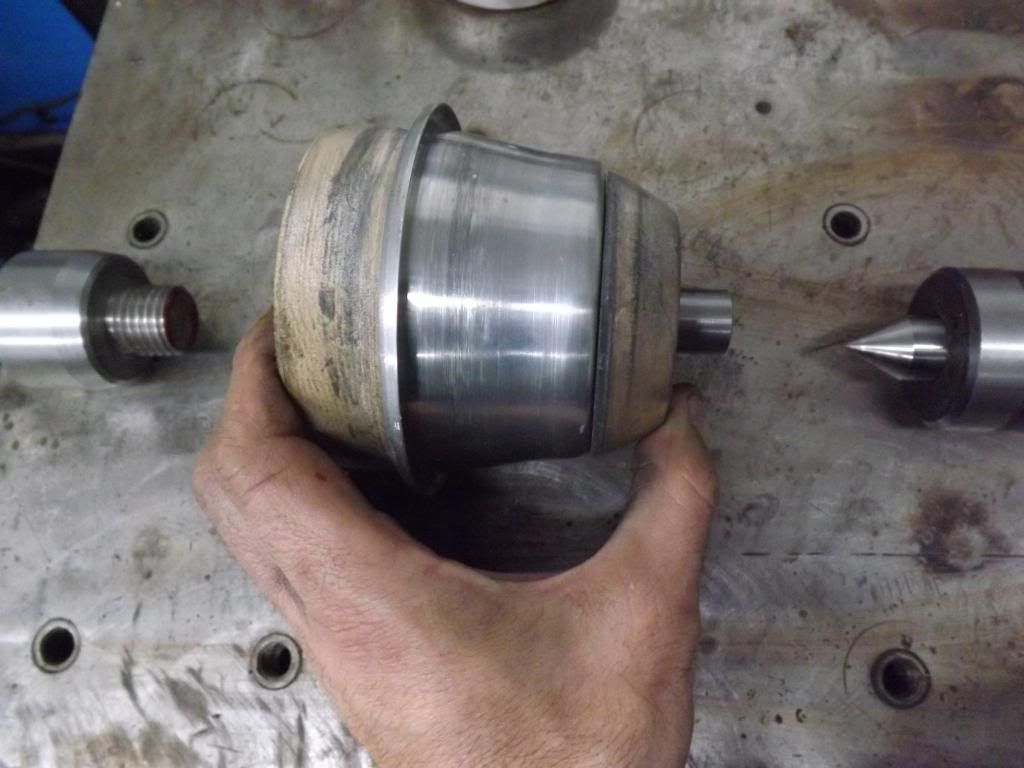

The pics will try to show how I homebrewed the tooling.

ETA: I am having technical problems with the photos.

You'll have to rig up a spinning rest and figure out a proper tailstock center (needs more clearance).

The pics will try to show how I homebrewed the tooling.

ETA: I am having technical problems with the photos.

Jon Bohlander

Stainless

- Joined

- Apr 22, 2003

- Location

- Topeka KS

Threaded adapter goes in the 3jaw, screw the form on the adapter, then the follow rest, an adapter so the pressure from the tailstock doesn't destroy the follower, and live center.

Different shapes from same form.

Couple different forms and different spun parts from them. You are not supposed to have lines in the part. That is operator error.

Different shapes from same form.

Couple different forms and different spun parts from them. You are not supposed to have lines in the part. That is operator error.

Jon Bohlander

Stainless

- Joined

- Apr 22, 2003

- Location

- Topeka KS

Lubricant. Toilet wax ring melted down and poured into toilet paper tube to make a crayon.

Tool rest

From top: trim,half round, ball & finger tools. I forgot the backtool which is simply a pointed piece of maple that supports the back side of the blank. Opposite the tool, between the blank & form.

magicmaker

Hot Rolled

- Joined

- Oct 7, 2006

- Location

- Tucson, AZ

For those interested, I have posted a pdf showing the process I used to spin a set of .094" thick copper cups. I have done thousands of spinnings for magicians around the world. This is an example of one such item. Spinning is alive and well.

http://jamesriser.com/Magic/HeavyRiserStageAndStreetCups.pdf

Enjoy. BTW - the lathe was a 26" Haag industrial spinning lathe. The bearings are around 6" Timken and the live center is the traditional heavy duty spinners center.

Jim

http://jamesriser.com/Magic/HeavyRiserStageAndStreetCups.pdf

Enjoy. BTW - the lathe was a 26" Haag industrial spinning lathe. The bearings are around 6" Timken and the live center is the traditional heavy duty spinners center.

Jim

Products includes car metal as well.As normally metal spinning performed by hand, but using metal spinning machinery such as a lathe is to achieve good metal spinning results. This method used in industrial and personal machine shops. Metal spinning employs a rotating metal disc to shape a work piece by causing the metal to flow into a predetermined shape. Mostly this process frequently used to create rounded metal parts and products.

asset tags

coolhand03

Cast Iron

- Joined

- Nov 15, 2012

- Location

- Kaibab Plateau, AZ

this method is definatly alive and well. i worked for an atv and gocart wheel manufacturer, that produced thier wheels this way. all CNC, standard single turret lathes. each run would produce one wheel half, then they went to the other side of the shop for welding.

Similar threads

- Replies

- 10

- Views

- 491

- Replies

- 48

- Views

- 2K