A DRO is a system comprised of several components. The items which must "fit" the machine are the scales, one for each axis of measurement. A mill DRO usually has three scales, X, Y, and Z. The X axis is the side-to-side travel of the table. The Y axis is table front-to-back, and the Z axis is the table height, controlled by the handle to raise or lower the knee.

It's possible to install a Z-axis scale on the machine quill. The readout for this scale is usually not coupled with the knee Z-axis scale. You position the knee as desired and lock it in place. Then you use the Z-axis readout on the quill to determine the vertical position of the tool.

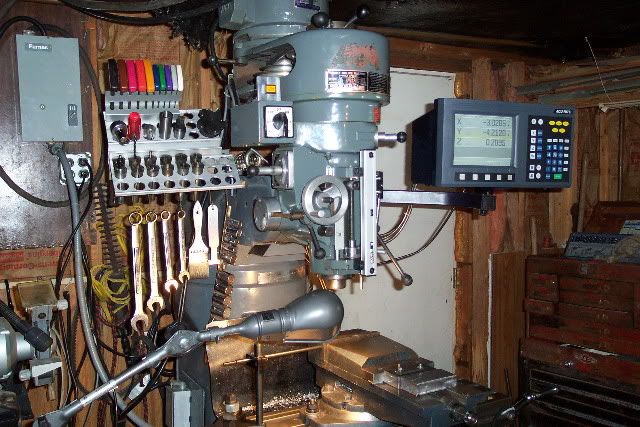

I have a four-axis system on my Bridgeport, with three scales on the knee and one on the quill, as shown below. The top readout is the quill. I believe this is the most versatile and accurate system you can put on a mill.

The other system component is the display and control box. This has a keypad for control and numeric entry, so you have to mount it somewhere within arm's reach. A complete system will include a mounting bracket with a long arm to support the box. This allows you to move the display to a convenient position.

On a Bridgeport machine the arm mounts to the top of the ram with a single large bolt. The arm swings around, pivoting on that bolt. The arm is large, about 1.5" square steel tubing.