jmp

Cast Iron

- Joined

- Nov 8, 2001

- Location

- Mechanicsville, Va

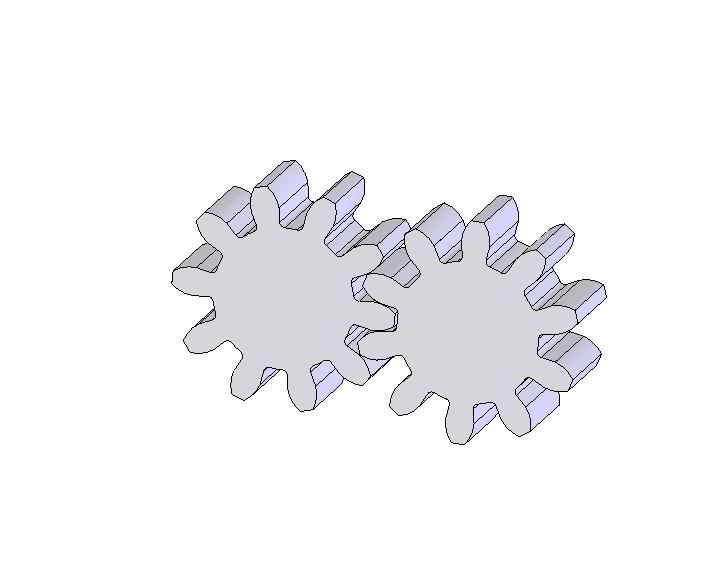

I need to cut a bunch of ten tooth gears and am not sure which cutter I need. I see that a no. 8

cutter will do down to 12 teeth but see no cutter listed for 11 or below. I sort of understand (I think) the special considerations for cutting these low tooth count gears but am wondering if off the shelf cutters exist. The gear in question is small .300 dia. I've looked through machinery's handbook about this till my head hurts. I was REALLY hoping stock drive products or boston gear would have these gears ready made but no luck there or anywhere else. Any thoughts?

Thanks,

Mike

p.s. not sure of what the pressure angle is yet.

cutter will do down to 12 teeth but see no cutter listed for 11 or below. I sort of understand (I think) the special considerations for cutting these low tooth count gears but am wondering if off the shelf cutters exist. The gear in question is small .300 dia. I've looked through machinery's handbook about this till my head hurts. I was REALLY hoping stock drive products or boston gear would have these gears ready made but no luck there or anywhere else. Any thoughts?

Thanks,

Mike

p.s. not sure of what the pressure angle is yet.