First and foremost, I have no manual, no information for this lathe. Research has turned up nothing. I've spoken with Tony at UK Lathes, nothing.

I have two choices, figure out what to use or leave whats in the sump there. I prefer not to leave the old oil in as I suspect it contaminated with cast iron as the rest of the lathe was.

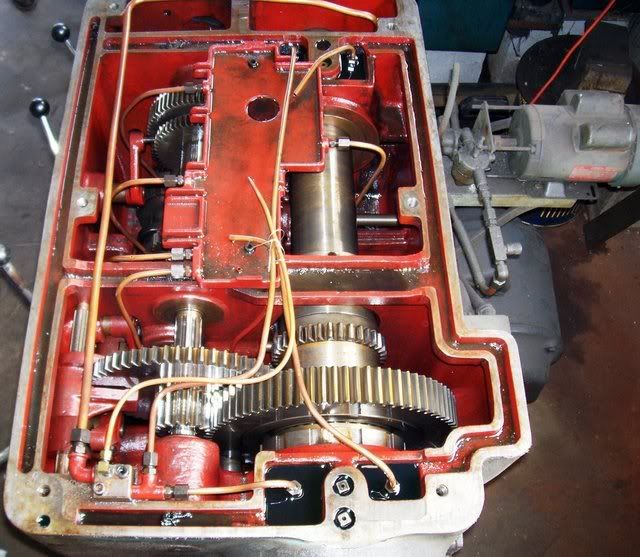

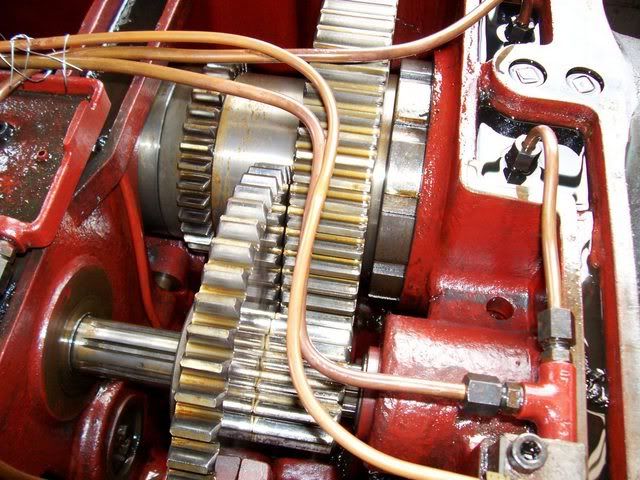

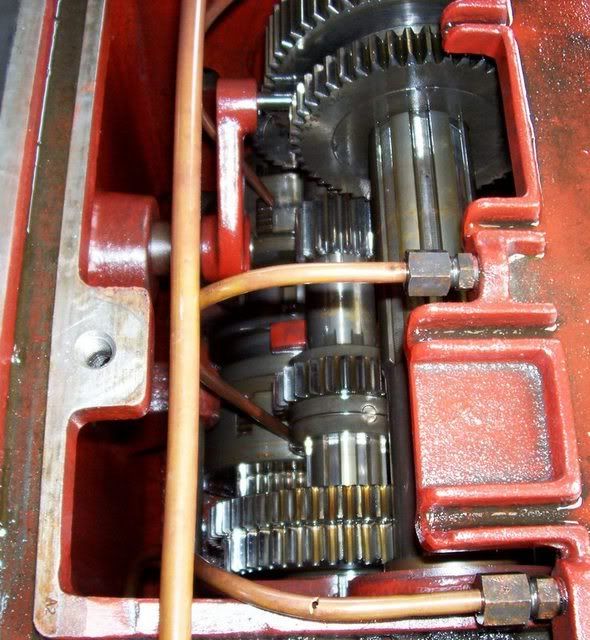

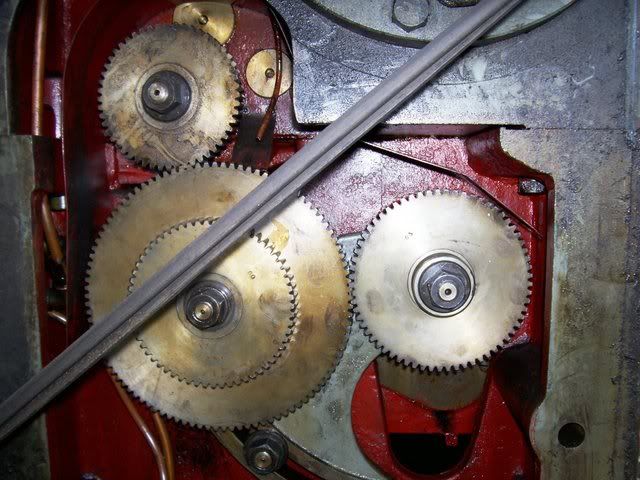

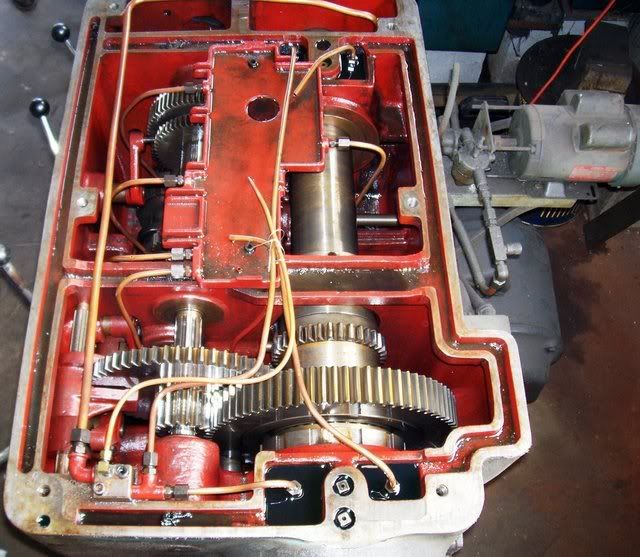

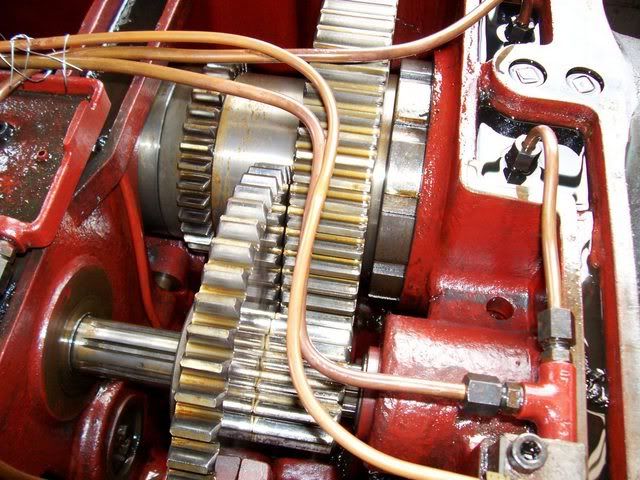

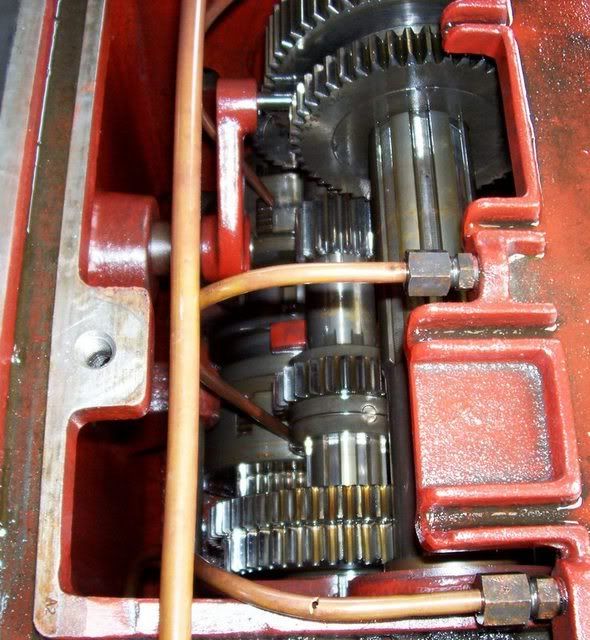

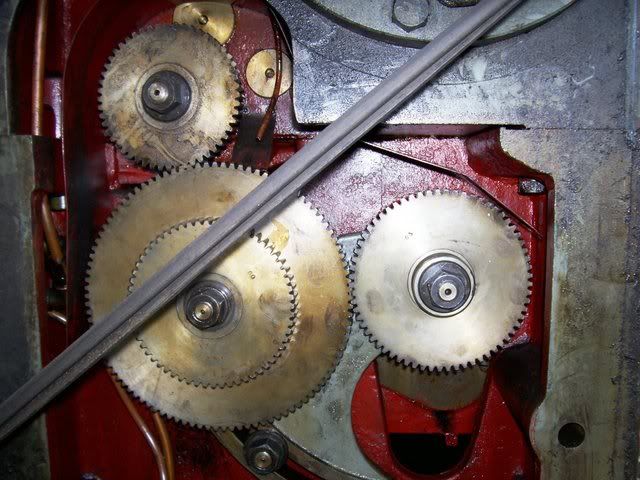

This is the 30" Progres "free for the taking" ebay lathe.

The last coat of paint will be applied Friday night. Reassembly on Saturday. Here are some photo's of the innards.

Here is one of the external pump:

Thanks for any input,

Lee

Edit: the gearbox has clutches.

I have two choices, figure out what to use or leave whats in the sump there. I prefer not to leave the old oil in as I suspect it contaminated with cast iron as the rest of the lathe was.

This is the 30" Progres "free for the taking" ebay lathe.

The last coat of paint will be applied Friday night. Reassembly on Saturday. Here are some photo's of the innards.

Here is one of the external pump:

Thanks for any input,

Lee

Edit: the gearbox has clutches.