How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Procut mill/drill?

- Thread starter Rod MI

- Start date

- Replies 16

- Views 11,396

That sort of machine is best discussed on a home shop machinist forum such as

http://bbs.homeshopmachinist.net

http://bbs.homeshopmachinist.net

toastydeath

Hot Rolled

- Joined

- Jan 6, 2007

- Location

- Newark, DE

What I never understood is why someone would want to advertise the "drill" part on one of those things. Does that really need to be advertised? Do they think a mill can't drill? I guess I've been wrong, having put drills in milling machines all this time.

Mike C.

Diamond

- Joined

- Nov 25, 2004

- Location

- Birmingham, AL

By calling it a "mill/drill" they make it easier to identify as a total POS. Truth is, it is a sorry excuse for a mill and the extremely limited space under the spindle makes it a useless drill.

precisionworks

Diamond

- Joined

- Apr 20, 2005

- Location

- Benton, IL USA

Never heard of that one. The Rong Fu or Enco brands are always on sale, look here.Is anyone familiar with this brand name?

I've drilled thousands of holes with my Enco M/D, and it's paid for itself many times over. Plus it does a nice job with solid carbide end mills up to 1", much better than the clapped out Bridgeport at work.

Mill/Drills often show up in the For Sale section of the forum, usually in the $500 range. I'd be hesitant about the Pro Cut, only because it's an unknown.

-----------------

Barry Milton

gradstdnt_99

Hot Rolled

- Joined

- Aug 17, 2004

- Location

- USA, Midwest

I started with a mill/drill and have since added a CNC mill. Although the CNC mill has handwheels for manual operation, it lacks a manual quill. The mill drill is still a great tool for quick drilling/milling work. Mine has power downfeed which is also very nice for boring work. I thought about getting rid of it when I got my CNC mill but it's just bee too handy. It really is a very good drill press and an OK mill.

Andreas

Aluminum

- Joined

- Mar 4, 2006

- Location

- UPPSALA SWEDEN

It is the other way around folks. It's a Mill/Drill

that can't mill. They are good for keeping boats of up to 10' still while you're fishing.

Andreas Proun owner of such POS

that can't mill. They are good for keeping boats of up to 10' still while you're fishing.

Andreas Proun owner of such POS

precisionworks

Diamond

- Joined

- Apr 20, 2005

- Location

- Benton, IL USA

IMO, it does 90% of the work done on a Bpt at 1/4 the cost. I run a Bpt a work, the mill/drill at home, both are 2HP.It's a Mill/Drill

that can't mill.

Sure, the head on the Bpt will swing left/right, plus it will nod up/down. Features that I use perhaps once a year, if that. The Bpt table is larger in depth & length, which is usually an advantage.

Will I ever buy a Bpt to replace the mill/drill, probably not. The two machines are far too similar, and both have somewhat limited capability. Would I buy a knee mill with a 40 Taper spindle, boxed ways & a larger spindle drive - in a heartbeat.

---------------

Barry Milton

deere_x475guy

Aluminum

- Joined

- Dec 6, 2005

- Location

- Eaton Rapids Mi

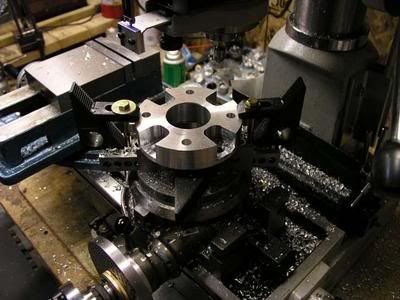

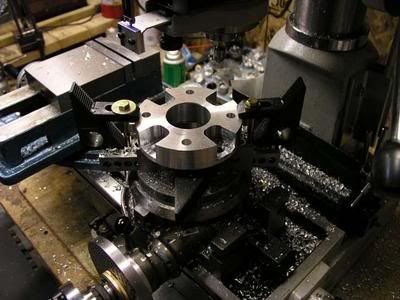

Rod, this first mill is a round column mill/drill I bought new from Production Tools 4 years ago. It was a PITA to use if you ever had to raise the head and be back on zero after changing tools. I made a few of these quad wheel spacers and a few other things and ultimately sold it on Ebay after having it only 3 months. Lots of guys are doing nice work with them. I just didn't have the patience to fuss with realining the head.

I bought this mill from Wholesale Tools in Detroit right after I sold the round column. I had this one about 3 years. Did lots of work with and and for the most part I enjoyed using it.

Not to long ago I found this mill locally where I could run it and know what I was getting into. I sold the dovetail column on Ebay and bought this one. Granted I don't have near the machining time on this one that I did on the other two but here are my observations of have a heavier knee mill.

It's easier to set parts up in (there is just more room).

The cuts appear better on this one. I just took a .05 cut at 190 rpm with a 3" end mill on some 1018 cold rolled. The finish was great and didn't even sound like it was pounding anything to death. This end mill on either of the other machines would have had them beating them selfs up.

In the end I would recommend going with at least a dovetail mill. Then just don't push the machine and you will be fine. Mine served me well.

Good luck

Bob

I bought this mill from Wholesale Tools in Detroit right after I sold the round column. I had this one about 3 years. Did lots of work with and and for the most part I enjoyed using it.

Not to long ago I found this mill locally where I could run it and know what I was getting into. I sold the dovetail column on Ebay and bought this one. Granted I don't have near the machining time on this one that I did on the other two but here are my observations of have a heavier knee mill.

It's easier to set parts up in (there is just more room).

The cuts appear better on this one. I just took a .05 cut at 190 rpm with a 3" end mill on some 1018 cold rolled. The finish was great and didn't even sound like it was pounding anything to death. This end mill on either of the other machines would have had them beating them selfs up.

In the end I would recommend going with at least a dovetail mill. Then just don't push the machine and you will be fine. Mine served me well.

Good luck

Bob

deere_x475guy

Aluminum

- Joined

- Dec 6, 2005

- Location

- Eaton Rapids Mi

Rod, I had a friend come out with a huge tracked BobCat with forks. He unload this mill and set it close enough that a short roll on on 3, 4' long pieces of black pipe and it was in place where you see it. He also unloaded another basket case Chaviler Mill and the Harig 6 x 18 surface grinder for me.

SteelCutter

Hot Rolled

- Joined

- Oct 21, 2006

Yikes, this dang page is wider than my

(_i_) <<<< click on that thingie to see what I mean

deere_x475guy, how much did that Enco run you?

looks nice, I've been eye'ing them for a while, is it accurate? rigid? and does it come with a DRO or do they offer a Retrofit like Prototrak, anilam or such???

SteelCutter

(_i_) <<<< click on that thingie to see what I mean

deere_x475guy, how much did that Enco run you?

looks nice, I've been eye'ing them for a while, is it accurate? rigid? and does it come with a DRO or do they offer a Retrofit like Prototrak, anilam or such???

SteelCutter

deere_x475guy

Aluminum

- Joined

- Dec 6, 2005

- Location

- Eaton Rapids Mi

Steelcutter, I gave $500 for the mill and $300.00 for the Harig grinder and he gave me the basket case Chaviler 9x49 mill. The Mill was new in 1988 and the grinder was new in 88 also.

The mill is very rigid and and it had a burnt up Fagor DRO on it. The scales are supposedly good but the power source is fried. I have a new 3 axis coming. As far as accuracy goes it has some wear as can be expected and I have learned how to compensate for it. All in all I am very happy with the upgrade.

The mill is very rigid and and it had a burnt up Fagor DRO on it. The scales are supposedly good but the power source is fried. I have a new 3 axis coming. As far as accuracy goes it has some wear as can be expected and I have learned how to compensate for it. All in all I am very happy with the upgrade.

SteelCutter

Hot Rolled

- Joined

- Oct 21, 2006

Homany dineros did the Enco run you? you know, dineros, pesos, dollars, yen, $$$$$, how many?????????

SteelCutter

SteelCutter

woody_rod

Aluminum

- Joined

- May 13, 2007

- Location

- Western Australia

From my research, all of about 2 weeks on this subject, I discovered far too many negative comments about the round column "mill/drill" in this size. I was looking to buy one, but found a second (third, fourth??) hand Parkson universal mill that weighs about 2 tons, which was about the same price as one of Chinese ones.

I also met a guy that is a friend of my fathers, he has a mill exactly like the one shown in deere's post, but with a round column. They are all pretty much the same, bar weird names and such.

After realising that the head can either move during machining, or is a pain to keep centered, I stayed right away from them. The second thing to do is to buy the same mill with a dovetail column - they are probably pretty good considering the price. If you have the room, buy an older horizontal mill, they are vastly more capable, albeit heavy and not so friendly on smaller parts. They are also cheap, because everyone seems to be buying BPT clones from china.

I also met a guy that is a friend of my fathers, he has a mill exactly like the one shown in deere's post, but with a round column. They are all pretty much the same, bar weird names and such.

After realising that the head can either move during machining, or is a pain to keep centered, I stayed right away from them. The second thing to do is to buy the same mill with a dovetail column - they are probably pretty good considering the price. If you have the room, buy an older horizontal mill, they are vastly more capable, albeit heavy and not so friendly on smaller parts. They are also cheap, because everyone seems to be buying BPT clones from china.

Similar threads

- Replies

- 5

- Views

- 470

- Replies

- 2

- Views

- 106

- Replies

- 2

- Views

- 218