How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6061 Spotting While Machining??

- Thread starter ccater1

- Start date

- Replies 35

- Views 7,640

G

guest

Guest

Have you looked at it with a loupe?Also, is there any option to post a larger image? Not sure if you can see the spots in my linked image above or not.

I can't tell by the pics if it's impurity or inclusion or what. If you have any more material it would be interesting to take some skim cuts and see what it looks like at .010" steps.

WILLEO6709

Diamond

- Joined

- Nov 6, 2001

- Location

- WAPELLO, IA USA

its your coolant- some types make black spots on aluminum

partsproduction

Titanium

- Joined

- Aug 22, 2011

- Location

- Oregon coast

If the OP is indicating the lighter colored areas, I've seen that many times on aluminum alloys and especially brass and bronze alloys when machining.

I too have always wondered what that is. It's almost like some weakness in the base material that shows up on the finish, or softer areas from poor heat treating. The shapes are usually crystalline in shape.

Sometimes they are large like the ones in the photo and sometimes they are smaller.

I too have always wondered what that is. It's almost like some weakness in the base material that shows up on the finish, or softer areas from poor heat treating. The shapes are usually crystalline in shape.

Sometimes they are large like the ones in the photo and sometimes they are smaller.

Larry Dickman

Titanium

- Joined

- Jan 30, 2014

- Location

- Temecula, Ca

Couple suggestions. When you take a picture of a part, turn the flash off, otherwise you get a ton of glare, like you did. Also, try not to post it using Botophuckit. I don't need to load a bunch of spam along with your picture.

Did you wash the part off? Reason I ask, there's something in our water here, don't know what it is. But if I swish a part off in a bucket of dish soap, and then throw it in a bucket of water, I need to pull it out and blow it off immediately, or it starts growing little spot that are a bitch to get off.

Did you wash the part off? Reason I ask, there's something in our water here, don't know what it is. But if I swish a part off in a bucket of dish soap, and then throw it in a bucket of water, I need to pull it out and blow it off immediately, or it starts growing little spot that are a bitch to get off.

Have you looked at it with a loupe?

I can't tell by the pics if it's impurity or inclusion or what. If you have any more material it would be interesting to take some skim cuts and see what it looks like at .010" steps.

I'll try that and report back

its your coolant- some types make black spots on aluminum

I used wd40. Would that do it?

Dupa3872

Stainless

- Joined

- May 1, 2007

- Location

- Boston Hyde park Ma.

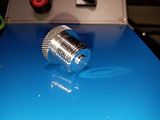

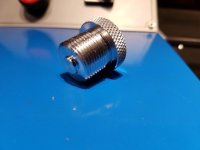

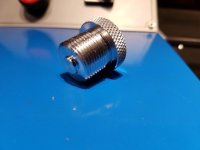

This looks very familiar. From the look of it these spots are all on the threads am I correct ? I cut tons of threads in 6061 and see this often, they are actually small tears in the material. I have tried different inserts and speeds, feeds, holders and can minimize it but they still happen. I use good quality domestic material for all my jobs and still get this. I don't see it in harder grades of aluminum.

Perhaps you can post some closer shots of the threads and someone can solve this problem

Make Chips Boys !

Ron

Perhaps you can post some closer shots of the threads and someone can solve this problem

Make Chips Boys !

Ron

If the OP is indicating the lighter colored areas, I've seen that many times on aluminum alloys and especially brass and bronze alloys when machining.

I too have always wondered what that is. It's almost like some weakness in the base material that shows up on the finish, or softer areas from poor heat treating. The shapes are usually crystalline in shape.

Sometimes they are large like the ones in the photo and sometimes they are smaller.

Yes! This exactly.

Couple suggestions. When you take a picture of a part, turn the flash off, otherwise you get a ton of glare, like you did. Also, try not to post it using Botophuckit. I don't need to load a bunch of spam along with your picture.

Did you wash the part off? Reason I ask, there's something in our water here, don't know what it is. But if I swish a part off in a bucket of dish soap, and then throw it in a bucket of water, I need to pull it out and blow it off immediately, or it starts growing little spot that are a bitch to get off.

How do you suggest I post the image? There's no option that I can find to post it directly here in the thread via my phone. Also, the part is so small that the flash was needed to show the spots well. But I did take a couple extra pics of the part without the flash, so I'll post those up, too.

This looks very familiar. From the look of it these spots are all on the threads am I correct ? I cut tons of threads in 6061 and see this often, they are actually small tears in the material. I have tried different inserts and speeds, feeds, holders and can minimize it but they still happen. I use good quality domestic material for all my jobs and still get this. I don't see it in harder grades of aluminum.

Perhaps you can post some closer shots of the threads and someone can solve this problem

Make Chips Boys !

Ron

Absolutely you are correct. It seems to be less noticeable with lighter cuts, but it's still there even making 1/2 thou cuts

I switched to full site and found the option to upload directly here. Not sure about image size rules but I'll resize if necessary. You can also see the spots slightly on the material as I was turning down to diameter for threading, however, I think I took the picture after turning several light cuts so the spots are not quite as pronounced as they were when I was taking ten thou cuts.

If the larger pictures are still not enough to get a good look I can break out my macro lens if my camera battery is still good. These pictures are the best my phone would take. I looked for a macro setting but didn't find one, so it wouldn't focus with the phone any closer than the current pictures.

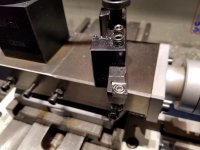

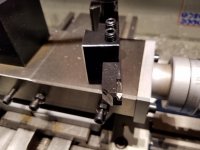

Just used the same piece of material and the same turning insert. I had to turn down roughly .140" at .010" before the metal started showing signs of spots. I used some wd40 early in the cut and it didn't seem to make any difference. One the material started to look spotty, I took two more cuts at .004" and the spots rared their ugly head. See attached.

Terry Keeley

Titanium

- Joined

- Oct 18, 2005

- Location

- Toronto, Canada eh!

As mentioned it looks like the tool is rubbing and not cutting clean, "no name" 6061 seems to have gotten more "gummy" in the last few years. Alcoa not as much.

Light cuts with carbide would make it worse, I'd try to hit the size with no less than a 0.010" cut. Have you tried a new insert? If you look at he cutting edge under a 5X loupe you'd be surprised how dull it may look. If it's sharp you could switch to a lower radius (sharper point) insert. Or better yet go with sharp HSS. Cutting fluid will help, WD40, Tapmajic for aluminum etc.

BTW, is your tool on center? Sorry, gotta ask...

Light cuts with carbide would make it worse, I'd try to hit the size with no less than a 0.010" cut. Have you tried a new insert? If you look at he cutting edge under a 5X loupe you'd be surprised how dull it may look. If it's sharp you could switch to a lower radius (sharper point) insert. Or better yet go with sharp HSS. Cutting fluid will help, WD40, Tapmajic for aluminum etc.

BTW, is your tool on center? Sorry, gotta ask...

This is what scotchbrite is for... if you're not tearing chunks out and the only issue is colour try some aluminum from a different manufacturer but this isn't something I'd be worried about.

If you have a die try threading a small section with that and see if the white marks appear on that too.

If you have a die try threading a small section with that and see if the white marks appear on that too.

Similar threads

- Replies

- 7

- Views

- 1K

- Replies

- 1

- Views

- 318

- Replies

- 1

- Views

- 322

- Replies

- 22

- Views

- 2K

- Replies

- 22

- Views

- 2K