Thomas Paine

Hot Rolled

- Joined

- Jan 9, 2013

- Location

- SE PA

Hey guys whats up, i haven't been here in awhile i kind of miss it compared to other forums, people are too nice on other forums.

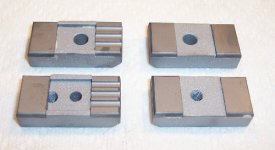

We have a few large steelcutting bandsaws with 2" and 2.5" wide blades.

The manufacturers are quoting insane prices for new bladeguides, do you guys have an referrals for a US companies that re-braze the carbide inserts in these? We tried doing it ourselves, but my young guys cant keep them flat or the carbide simply just falls off

Thanks for your help-

We have a few large steelcutting bandsaws with 2" and 2.5" wide blades.

The manufacturers are quoting insane prices for new bladeguides, do you guys have an referrals for a US companies that re-braze the carbide inserts in these? We tried doing it ourselves, but my young guys cant keep them flat or the carbide simply just falls off

Thanks for your help-