Chris Epping

Aluminum

- Joined

- Dec 28, 2011

- Location

- Nebraska

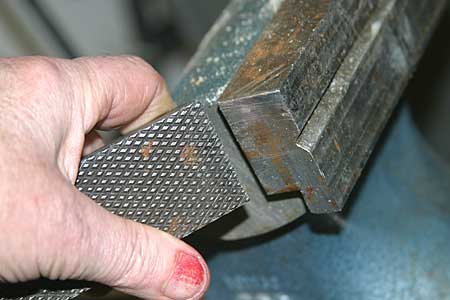

I'm looking at purchasing a Wilton vise for general mechanic and machine shop use. Pretty much have to order one as they are high enough priced that none of the local shops have one you can look at. I was wondering what everyone's experience had been with these vises and which model is the nicest to use for general work. I was looking at a 600S or model C3. I'll include links to Northern's catalog for pics. Need something that is heavy duty and well made without being clumsy and awkward to use. Any thoughts?

Wilton Pipe & Bench Vise — 6in. Jaw Width, Model# C-3 | Bench Vises| Northern Tool + Equipment

Wilton Serrated Machinist Bench Vise — 6in. Jaw Width, Swivel Base, Model# 600S | Bench Vises| Northern Tool + Equipment

Thanks,

Chris

Wilton Pipe & Bench Vise — 6in. Jaw Width, Model# C-3 | Bench Vises| Northern Tool + Equipment

Wilton Serrated Machinist Bench Vise — 6in. Jaw Width, Swivel Base, Model# 600S | Bench Vises| Northern Tool + Equipment

Thanks,

Chris