Trboatworks

Diamond

- Joined

- Oct 23, 2010

- Location

- Maryland- USA

I am looking at a run of 330 miles each way.

I can get a truck to run it to my shop for twice what I will spend on sandwiches and gas but like the ideal of picking up myself to avoid damage to machine.

Thoughts?

4 am leave and drive from DC to CT, load and run back down coast- maybe do the whole deal in a 16 hour day..

You guys have a will not drive further than rule?... LOL

Small fussy mill.. the seller will band to pallet so I have to trust the trucker to strap the top heavy widget so he doesn't roll it over or manage to not knock off any wheels or bend up the screws...

I can get a truck to run it to my shop for twice what I will spend on sandwiches and gas but like the ideal of picking up myself to avoid damage to machine.

Thoughts?

4 am leave and drive from DC to CT, load and run back down coast- maybe do the whole deal in a 16 hour day..

You guys have a will not drive further than rule?... LOL

Small fussy mill.. the seller will band to pallet so I have to trust the trucker to strap the top heavy widget so he doesn't roll it over or manage to not knock off any wheels or bend up the screws...

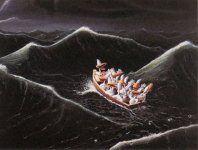

gotta love endurance racing.

gotta love endurance racing.

Turned out the trailer had been in a grass fire, didnt even scorch the paint but the tires....

Turned out the trailer had been in a grass fire, didnt even scorch the paint but the tires.... oh shoot- don't tell me..

oh shoot- don't tell me.. )

)