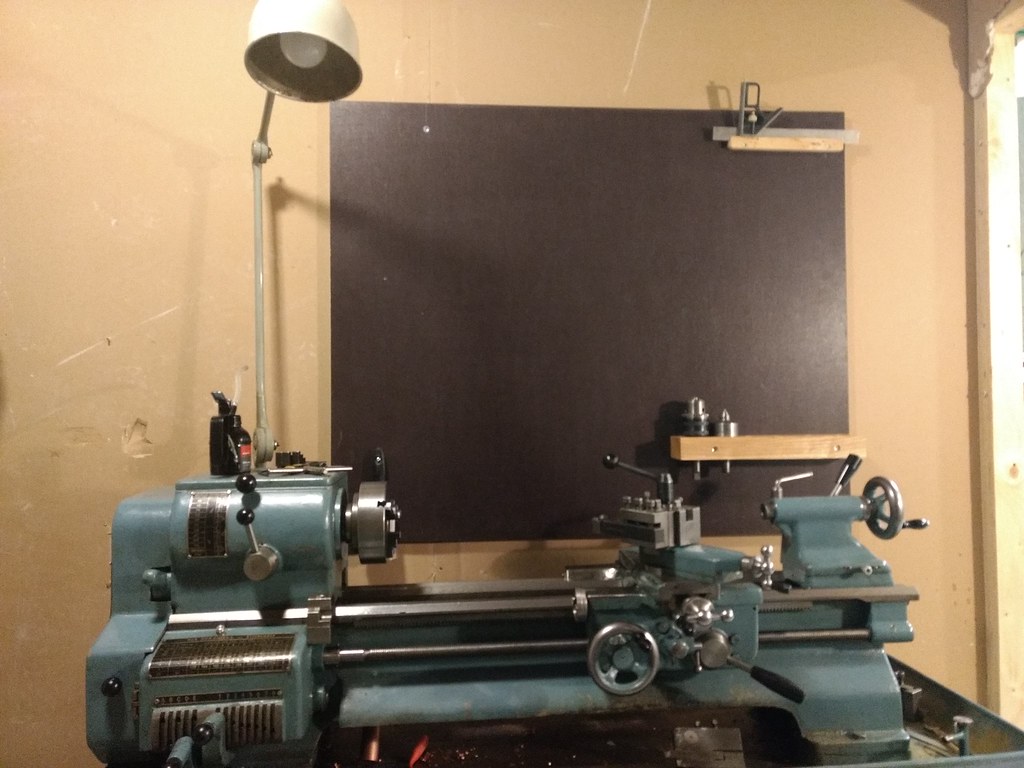

I have a Rexvalter VF-118 lathe, it's my first lathe, never really used it yet, I'm used to woodworking lathes but I am wanting to take the step into metal machining too, as it seems to come up a lot when I build, modify and renovate old machines.

The lathe comes with a 5" 3-jaw and 6" 4-jaw chuck and four QCTP holders of the swedish make Bergström. Kinda like Aloris.

I've been thinking about collet chucks, as in sometime in the future, in a few years maybe it would be a good investment. They seem like useful things to have. Been watching This Old Tony on youtube, and he has a lot of use from his 5C collet chuck.

I started researching collet chucks and it seems the 5C chuck is not recommended for a lathe of my size which has only a 20mm spindle bore (outer diameter 45/35mm). Then I started looking at ER-32 collet chucks, but it seems these aren't entirely recommended either, lots of people thought it was a bad idea so now I am unsure what's a good way to go for me and my lathe.

Some images of the lathe:

The lathe comes with a 5" 3-jaw and 6" 4-jaw chuck and four QCTP holders of the swedish make Bergström. Kinda like Aloris.

I've been thinking about collet chucks, as in sometime in the future, in a few years maybe it would be a good investment. They seem like useful things to have. Been watching This Old Tony on youtube, and he has a lot of use from his 5C collet chuck.

I started researching collet chucks and it seems the 5C chuck is not recommended for a lathe of my size which has only a 20mm spindle bore (outer diameter 45/35mm). Then I started looking at ER-32 collet chucks, but it seems these aren't entirely recommended either, lots of people thought it was a bad idea so now I am unsure what's a good way to go for me and my lathe.

Some images of the lathe: