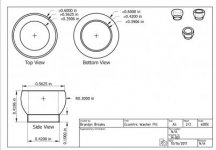

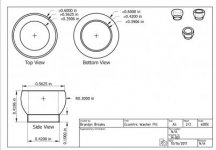

Hello everyone. New to the forum. Not a machinist myself, have a little experience though. First off, allow me to apologize if I'm not posting this in the proper area, wasn't quite sure where to post this. I've attached two screen captures of PDF files because the original PDF is too large to attach, but my questions are: a) How much do you suppose a machine shop would charge to produce four of each part, rough ball-park range? And b) Do you think these drawings are detailed enough; if not, what information are they lacking? I can always add information.

Thank you in advance for any help!

Thank you in advance for any help!