joem64

Plastic

- Joined

- Nov 12, 2013

- Location

- new jersey

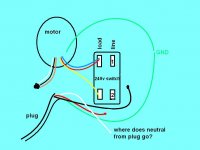

I picked this drill press up from a yard sale and am having trouble re-wiring it for 240v. I've attached pictures of the wire bundle going into the motor case (6 wires), the wire bundle going towards the on/off switch (5 wires) and the wiring diagram on the motor plate. I'm trying to connect a 4 wire pig tail to these wires. I understand that Line-1 and Line-2 are the hots (black and red from plug) and green to ground is obvious but how to a wire the white from pigtail? I read "insulate" orange black and white" but from where? There is orange black and white wires coming from the on/off and the motor housing. Does that mean join them all together to the white neutral coming from the pigtail? Any help would be greatly appreciated.