Tim Wells

Aluminum

- Joined

- Apr 22, 2007

- Location

- Dallas, GA

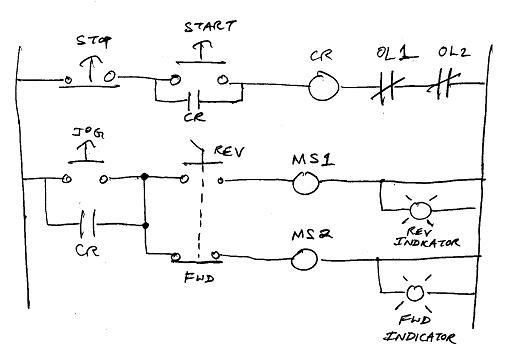

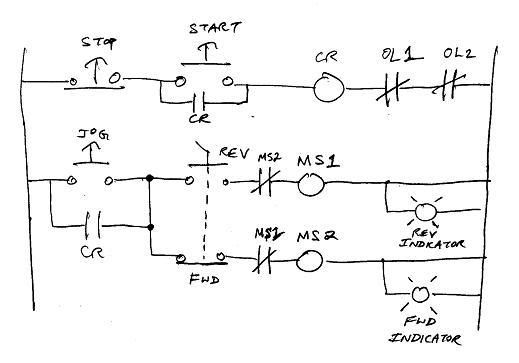

This is my first post and I'm desperate. I bought a used (1999) model# 110-2079 gap bed 18 speed lathe with an American motor on it. I didn't realize it at the time but the entire contactor box that goes behind the headstock is missing.

I contacted Enco about it and they are looking into replacement costs but they have yet to be much help. I can make the box easily enough.

What I need is a parts list of the contents of the box, better yet a nice bright closeup photo of the opened box and what's inside taken by one of you good gents that have one of these things.

I feel certain that I could get the transformer, fuses, relays and such off the shelf somewhere rather than having to order it from China for petes sake. There is a crappy B&W photo of it on the manual I downloaded but it's so poor you can't tell what any of it is or what numbers are on each component so you'd have something to go by when looking for a replacement.

Can someone bail me out?

I contacted Enco about it and they are looking into replacement costs but they have yet to be much help. I can make the box easily enough.

What I need is a parts list of the contents of the box, better yet a nice bright closeup photo of the opened box and what's inside taken by one of you good gents that have one of these things.

I feel certain that I could get the transformer, fuses, relays and such off the shelf somewhere rather than having to order it from China for petes sake. There is a crappy B&W photo of it on the manual I downloaded but it's so poor you can't tell what any of it is or what numbers are on each component so you'd have something to go by when looking for a replacement.

Can someone bail me out?