Hello,

I'm machining a mast step out of G10 for my friends boat. At work I have access to a Matsuura CNC mill with a 10k spindle, however, it is not very insulated. I know G10 likes high RPM, and 10k is alright, but I get the impression that faster would be better. I'm also worried about getting dust into the machine and the rest of the shop, as I've mentioned, it's not enclosed well. Even with a vac I expect it would get messy fast. We have been working with MDF in this manner recently and there is a light dusting everywhere.

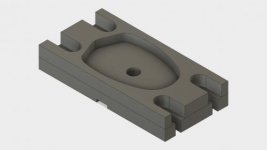

My question is how practical would it would be to use my 20k spindle handheld router in an glovebox-like enclosure? I figure I could make a template to clamp to the 2" thick G10. My thought is if I get the right tooling (hopefully with a guide bearing) this would be a fairly strait forward project. I'm not sure if I could get a G10 endmill with that bearing though. So unless anyone knows some magical tool just for this use, I'd probably be stuck with something like in the link below, or I'd have to get a legit composite endmill and use the shank as the guide. Keep in mind this is a one-piece for my friend. I've included a picture of my design. I'd appreciate any constructive responses you might have. Thanks.

CMT 812.691.11B Pattern Bit with Bearing, 1/2-Inch Shank, 3/4-Inch Diameter, Carbide-Tipped - Straight Router Bits - Amazon.com

I'm machining a mast step out of G10 for my friends boat. At work I have access to a Matsuura CNC mill with a 10k spindle, however, it is not very insulated. I know G10 likes high RPM, and 10k is alright, but I get the impression that faster would be better. I'm also worried about getting dust into the machine and the rest of the shop, as I've mentioned, it's not enclosed well. Even with a vac I expect it would get messy fast. We have been working with MDF in this manner recently and there is a light dusting everywhere.

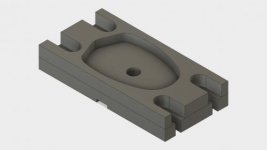

My question is how practical would it would be to use my 20k spindle handheld router in an glovebox-like enclosure? I figure I could make a template to clamp to the 2" thick G10. My thought is if I get the right tooling (hopefully with a guide bearing) this would be a fairly strait forward project. I'm not sure if I could get a G10 endmill with that bearing though. So unless anyone knows some magical tool just for this use, I'd probably be stuck with something like in the link below, or I'd have to get a legit composite endmill and use the shank as the guide. Keep in mind this is a one-piece for my friend. I've included a picture of my design. I'd appreciate any constructive responses you might have. Thanks.

CMT 812.691.11B Pattern Bit with Bearing, 1/2-Inch Shank, 3/4-Inch Diameter, Carbide-Tipped - Straight Router Bits - Amazon.com