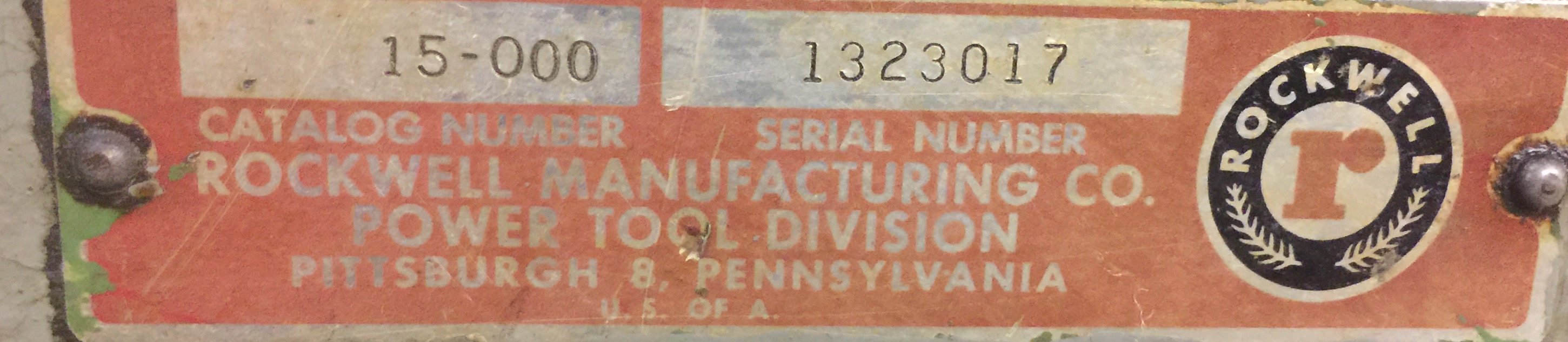

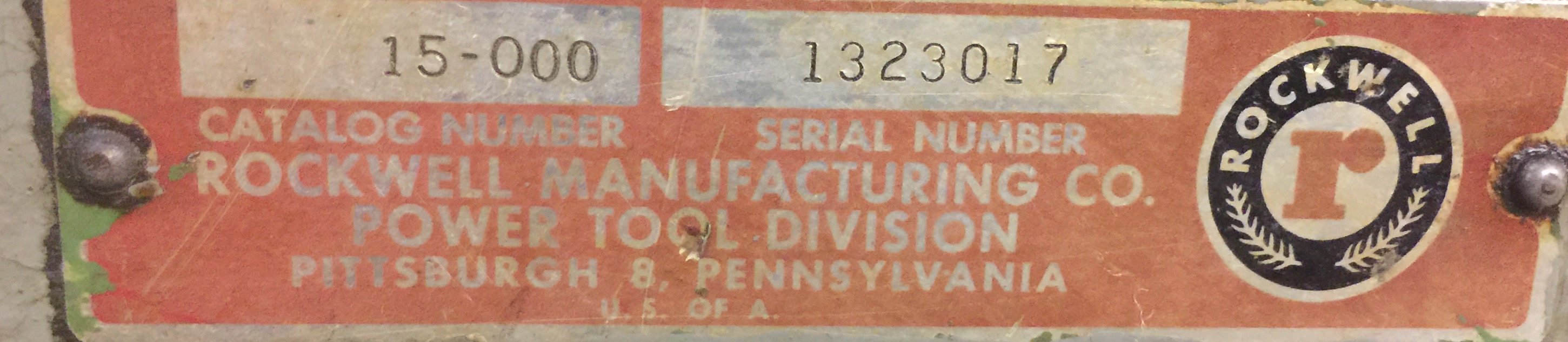

Trying to get the balance mech put back in correct pos on a Rockwell 15-000 balanced-head drill. Failed to get an overall pic, sry, and couldn't find much on web except a pic of the balancer parts, copied below. As u can see the chain is off the pulley and rotated around the column about 180 degrees, but still under 100 lbs or more of spring tension. I'm cautious about disassembling things under lots of spring tension/compression so have stopped to ask how to proceed here. There are two screws a few inches from top of column, on opposite sides of column. Drill was in this condition when I got it so I don't know how it got that way. But it all works except that part so I want to fix it. Help-drawings, manual, experience?