rule308x

Plastic

- Joined

- Apr 20, 2012

- Location

- USA, Near Nashville Tennessee

Greetings,

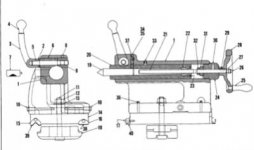

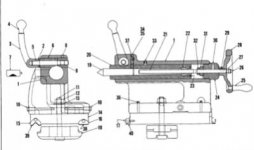

I have a 15 x 30 Leblond Regal Servoshift. I believe it was manufactured in the early 1970s (8C serial number) It appears to be in very good condition overall but there is a problem with the tailstock. The bronze or brass nut which engages the screw has been severely damaged and needs to be replaced. I have a copy of the military manual for this series which shows that the nut is replaceable but does not give a proceedure to disassemble the tailstock. The nut itself (#22) appears to be held in by two hex screws, but I'm not sure if the nut itself is threaded on the outside and screws into the tailstock spindle, if it is held in place with some sort of adhesive in addition to the screws, or if it is pressed in. I have removed the two hex screws but the nut is not free.

I was hoping that someone could instruct me in the recommended way to remove the spindle itself from the tailstock and the nut from the tailstock spindle. I have unscrewed the tailstock cap/screw/handle assembly and loosened the binder level assembly but there is a pin on the far side of the tailstock that I don't know how to remove (#7). Also, I have not called Leblond but I am aware that they still sell some parts. Is this part obtainable from other sources or from Leblond only? Alternately I could make one if a premade part is expensive.

I can provide a bigger picture from the manual or a picture of my actual pieces, I didn't want to upload anything too big...

Thanks in advance for any suggestions.

Jeff

I have a 15 x 30 Leblond Regal Servoshift. I believe it was manufactured in the early 1970s (8C serial number) It appears to be in very good condition overall but there is a problem with the tailstock. The bronze or brass nut which engages the screw has been severely damaged and needs to be replaced. I have a copy of the military manual for this series which shows that the nut is replaceable but does not give a proceedure to disassemble the tailstock. The nut itself (#22) appears to be held in by two hex screws, but I'm not sure if the nut itself is threaded on the outside and screws into the tailstock spindle, if it is held in place with some sort of adhesive in addition to the screws, or if it is pressed in. I have removed the two hex screws but the nut is not free.

I was hoping that someone could instruct me in the recommended way to remove the spindle itself from the tailstock and the nut from the tailstock spindle. I have unscrewed the tailstock cap/screw/handle assembly and loosened the binder level assembly but there is a pin on the far side of the tailstock that I don't know how to remove (#7). Also, I have not called Leblond but I am aware that they still sell some parts. Is this part obtainable from other sources or from Leblond only? Alternately I could make one if a premade part is expensive.

I can provide a bigger picture from the manual or a picture of my actual pieces, I didn't want to upload anything too big...

Thanks in advance for any suggestions.

Jeff

Usually other confounding clues can lead you to some more understanding of the construction.

Usually other confounding clues can lead you to some more understanding of the construction.