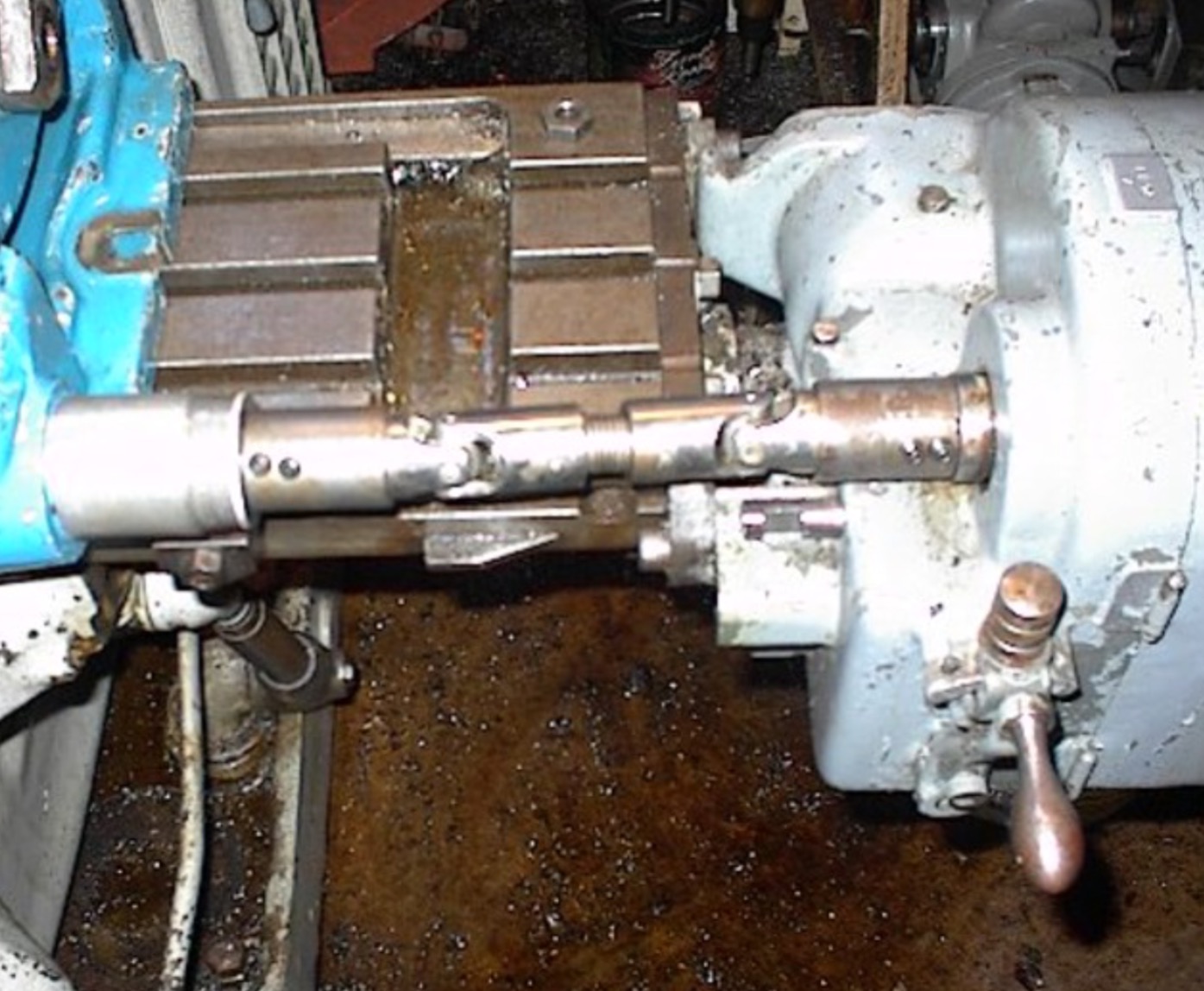

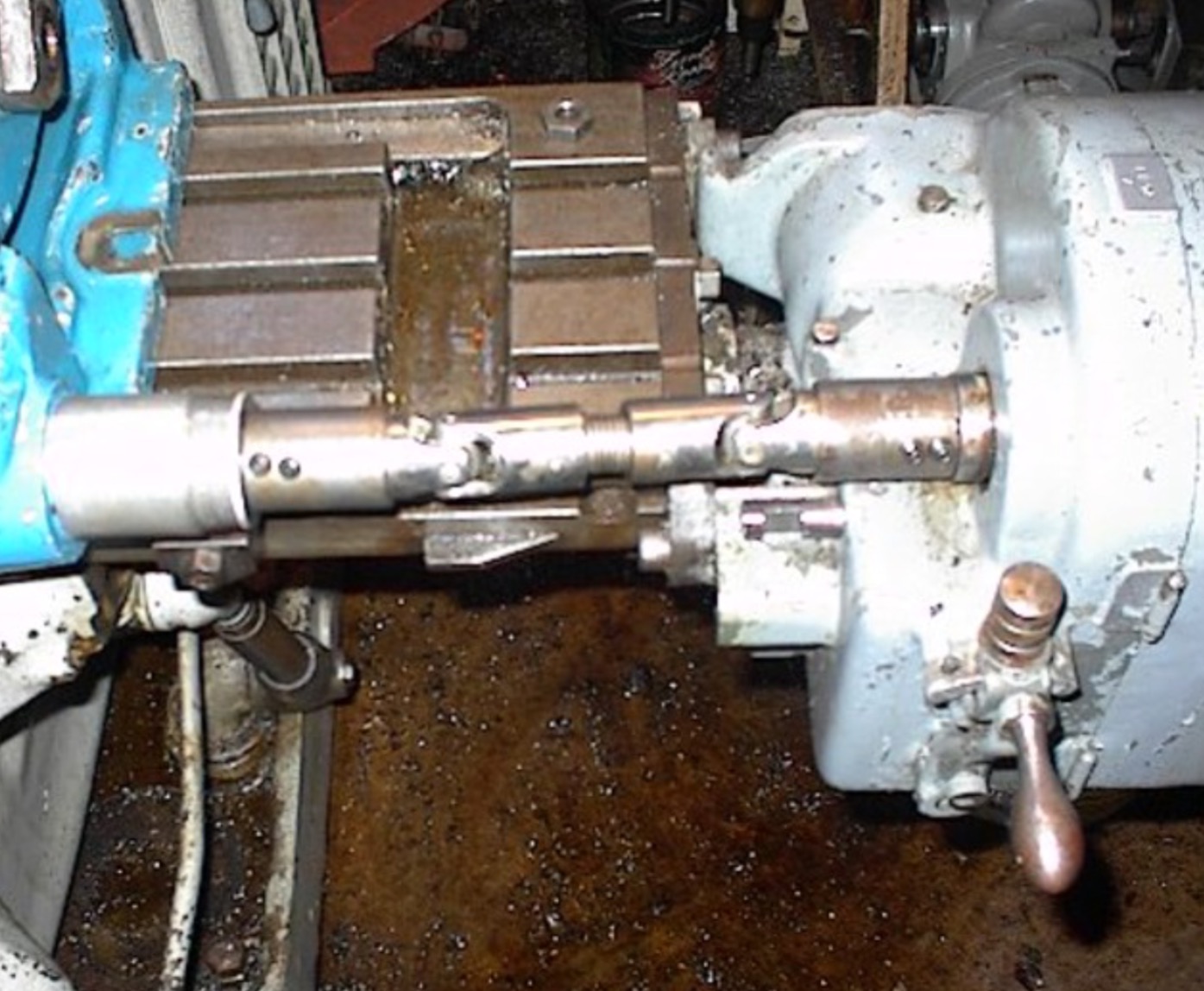

Michael Goleman posted these pix on the K&T Milwaukee Yahoo Group under "...Southern Engineering" Well, that it is, a double-jointed spline drive as shown to make up for the axial misalignment. I'd love to do that since I have the same type dividing head and a K&T 2CH vertical mill which is similar to that in the photos but unfortunately mine lacks the PTO head Mike's has on the right end of the table. I don't recall reading of any restrictions on borrowing photos from the group as long as credit was given.

Last edited: