good day all,

I'm new here, some info about me and why I'm posting looking for better than a hobby mill

I'm a part time bladesmith

home garage setup

I prefer plug and play setup for the most part

I prefer to buy once cry once

I'll be milling 1/8" slots in brass, 416 SS, silicon bronze

other light milling

drilling holes for folding knives

some tapping capability would be nice for small holes

power - 110 would be easiest, I can get 220 1 phase in my garage but it will cost me

DRO would be nice.

I work in an aerospace CNC machine shop but am not a machinist.

But I've run toolshops and machine shops and been a cad/cam programmer.

Found a Linley jog borer MK1A in very nice condition, power feed etc, no collets, I know that will cost me but I accept that. I know this is not a milling machine but can do light milling as I need,

Question - what's the going rate for one of these machines? the one I'm looking at is a 1/2 HP single phase

I believe this is the right machine for me as a part time knife-maker, let me make my argument to you.

single phase ready ( I dont need high HP) no need for phase convertor or more power

smaller size footprint than a knee mill

suitable for light slot milling

lighter weight at 800 lbs vs a knee mill (but still not a lightweight toy)

generally less costly since they are not desirable machines for most

disadvantages - collet availability,

Other considerations would be a Precision Matthews PM-25MV or PM-727M

thanks for some guidance and your opinions

regards

I'm new here, some info about me and why I'm posting looking for better than a hobby mill

I'm a part time bladesmith

home garage setup

I prefer plug and play setup for the most part

I prefer to buy once cry once

I'll be milling 1/8" slots in brass, 416 SS, silicon bronze

other light milling

drilling holes for folding knives

some tapping capability would be nice for small holes

power - 110 would be easiest, I can get 220 1 phase in my garage but it will cost me

DRO would be nice.

I work in an aerospace CNC machine shop but am not a machinist.

But I've run toolshops and machine shops and been a cad/cam programmer.

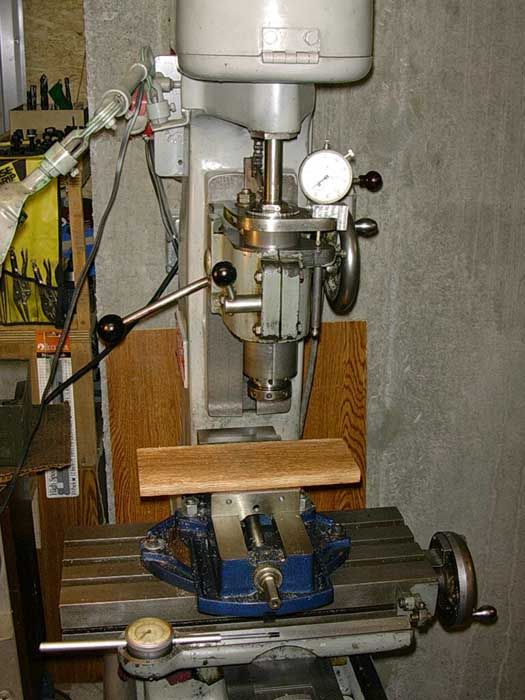

Found a Linley jog borer MK1A in very nice condition, power feed etc, no collets, I know that will cost me but I accept that. I know this is not a milling machine but can do light milling as I need,

Question - what's the going rate for one of these machines? the one I'm looking at is a 1/2 HP single phase

I believe this is the right machine for me as a part time knife-maker, let me make my argument to you.

single phase ready ( I dont need high HP) no need for phase convertor or more power

smaller size footprint than a knee mill

suitable for light slot milling

lighter weight at 800 lbs vs a knee mill (but still not a lightweight toy)

generally less costly since they are not desirable machines for most

disadvantages - collet availability,

Other considerations would be a Precision Matthews PM-25MV or PM-727M

thanks for some guidance and your opinions

regards