oeo2oo

Aluminum

- Joined

- Jun 16, 2004

- Location

- Lee, MA United States

I recently bought a Neuweiler Straight Line Engine Turning Machine, and I'm in the midst of disassembling it, cleaning it and putting it back together.

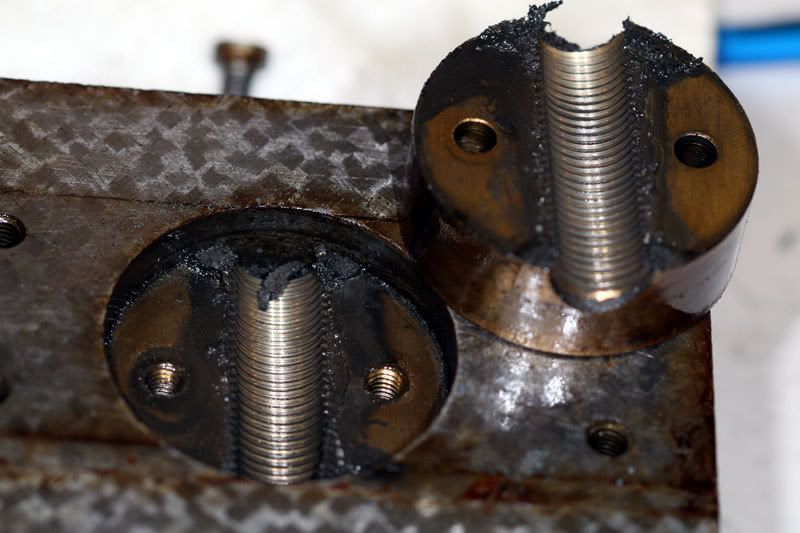

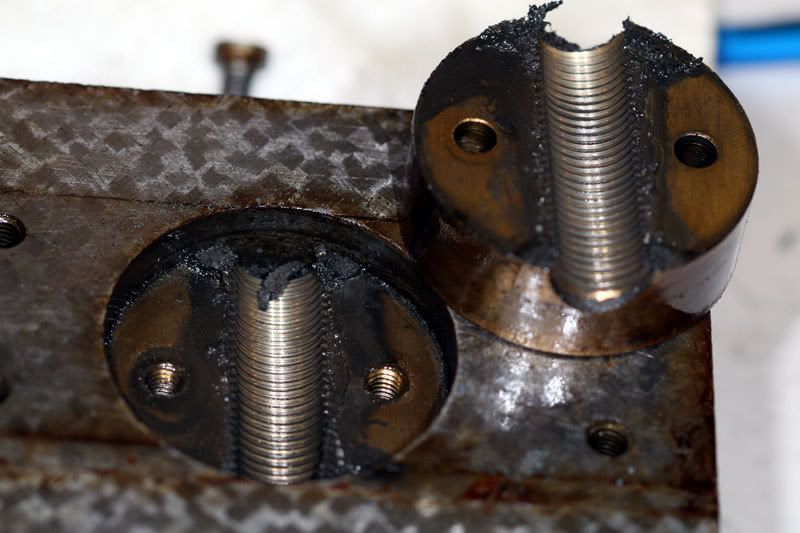

I have a couple of lubrication questions. First, there are some brass half-nuts on one of the lead screws, actually the cross slide lead screw. Now that gets used quite a bit when engraving with the machine. As I took it apart, it looked like this:

Seems like caked-on grease to me. So, should these really be greased, or would something like way oil work just as well, or better? It would be a fairly easy thing to apply oil to the lead screw by hand from time to time.

My second, and last question, concerns a rake and pinion that is used to raise and lower the main slide, which holds the chuck and the work piece. Everything is counterbalanced with weights, so it is fairly easy to raise and lower the slide. So, what should I use on the rack and pinion for lubrication? Oil or grease? Again, it is easy to access these, so applying any lubrication will be effortless.

I have a couple of lubrication questions. First, there are some brass half-nuts on one of the lead screws, actually the cross slide lead screw. Now that gets used quite a bit when engraving with the machine. As I took it apart, it looked like this:

Seems like caked-on grease to me. So, should these really be greased, or would something like way oil work just as well, or better? It would be a fairly easy thing to apply oil to the lead screw by hand from time to time.

My second, and last question, concerns a rake and pinion that is used to raise and lower the main slide, which holds the chuck and the work piece. Everything is counterbalanced with weights, so it is fairly easy to raise and lower the slide. So, what should I use on the rack and pinion for lubrication? Oil or grease? Again, it is easy to access these, so applying any lubrication will be effortless.