taiwanluthiers

Cast Iron

- Joined

- Dec 6, 2016

- Location

- Xinjhuan District, New Taipei City

I kinda delayed posting this a bit, but here it is...

So basically the lathe came with very little in way of accessory. Seeing it only cost $100 more than the PM1127 I can see why... What it has over the 1127:

1 inch more swing

1 inch more distance between center

REAL quick change gearbox (meaning you can make most threads without changing gears, though change gears are available if you want to do some uncommon threads, to date I have not changed any gears at all)

A more powerful BLDC motor (I only managed to bog it down cutting .04" on mild steel using WNMG 432 insert at a fast feed rate, and that was because it's a heavier cut insert, I need light to finishing inserts for this lathe)

D1-4 spindle (I think the 1127 has something else...)

So overall it's worth it over the 1127 especially the gearbox. I can thread Remington 700 actions, as well as many other stuff without ever touching the gears.

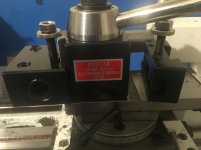

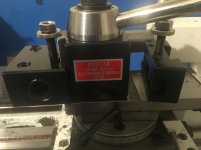

The lathe is ready for AXA QCTP that Precision Matthews sells, but I ended up installing a Bostar BXA tool post because I like to use some bigger tools (I mean, I'm not going to be making Abom79 cuts, my lathe is too small for this, but I feel being stuck to 1/2" inserts is limiting when the machine is designed for 5/8").

The original tool post goes on a spindle that is threaded 9/16" x 18, you loosen a set screw to take it off. However the spindle that came with the Bostar BXA is larger and the wrong pitch, so I had to machine it down until it fits the threaded hole in the compound (I mean that's what lathes are for, right??). I still had to mill down some tool holders because they are a little thick in the bottom so I was having some trouble centering the tool, but it still fits. Precision Matthews does not recommend it however because he feels the lathe is too small to use larger inserts.

I've gotten a Shars 4 jaw chuck (it did not come with one), the lathe shakes a little at certain RPM with that chuck on. The stock 3 jaw chuck did not shake at all at any RPM. Maybe I need to rebalance the thing... Not sure how to do that.

Overall the lathe is pretty good, plenty of power for its size and it's capable of gunsmithing due to its 1.5" spindle. I can basically fit barreled action into it. Need to make a spider for it.

So basically the lathe came with very little in way of accessory. Seeing it only cost $100 more than the PM1127 I can see why... What it has over the 1127:

1 inch more swing

1 inch more distance between center

REAL quick change gearbox (meaning you can make most threads without changing gears, though change gears are available if you want to do some uncommon threads, to date I have not changed any gears at all)

A more powerful BLDC motor (I only managed to bog it down cutting .04" on mild steel using WNMG 432 insert at a fast feed rate, and that was because it's a heavier cut insert, I need light to finishing inserts for this lathe)

D1-4 spindle (I think the 1127 has something else...)

So overall it's worth it over the 1127 especially the gearbox. I can thread Remington 700 actions, as well as many other stuff without ever touching the gears.

The lathe is ready for AXA QCTP that Precision Matthews sells, but I ended up installing a Bostar BXA tool post because I like to use some bigger tools (I mean, I'm not going to be making Abom79 cuts, my lathe is too small for this, but I feel being stuck to 1/2" inserts is limiting when the machine is designed for 5/8").

The original tool post goes on a spindle that is threaded 9/16" x 18, you loosen a set screw to take it off. However the spindle that came with the Bostar BXA is larger and the wrong pitch, so I had to machine it down until it fits the threaded hole in the compound (I mean that's what lathes are for, right??). I still had to mill down some tool holders because they are a little thick in the bottom so I was having some trouble centering the tool, but it still fits. Precision Matthews does not recommend it however because he feels the lathe is too small to use larger inserts.

I've gotten a Shars 4 jaw chuck (it did not come with one), the lathe shakes a little at certain RPM with that chuck on. The stock 3 jaw chuck did not shake at all at any RPM. Maybe I need to rebalance the thing... Not sure how to do that.

Overall the lathe is pretty good, plenty of power for its size and it's capable of gunsmithing due to its 1.5" spindle. I can basically fit barreled action into it. Need to make a spider for it.

This must be the ultimate snobbery - to own a machine branded by the owner of that one and the other one. AND German. And as we all know, German is golden.

This must be the ultimate snobbery - to own a machine branded by the owner of that one and the other one. AND German. And as we all know, German is golden.