Finegrain

Diamond

- Joined

- Sep 6, 2007

- Location

- Seattle, Washington

Hi guys,

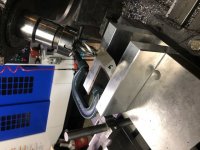

I need to put this compound chamfer on this part:

Part is 5.4" tall, and the chamfer is defined as .30", 45* on all 3 axes. So, looking at it from the front, the line where the chamfer starts is 45*. Same when looking from the right or the top. I'm pretty stupid when it comes to how to make compound angles .

.

Next challenge after figuring out what the angles are is how to mill it -- I first thought I'd just set the head of the manual mill to the right angles, but that's no good since the table is still going to move in plain old X and Y. Then I thought maybe I could get the angles right, then plunge an endmill into the corner, but that seems a bit sketchy.

Last resort is to just stick it in the VMC and let CAM figure it all out. But, I would like to know how to do this, in case I get something down the road that won't fit in the VMC or would be a PITA to fixture in the VMC.

Thanks, and regards.

Mike

I need to put this compound chamfer on this part:

Part is 5.4" tall, and the chamfer is defined as .30", 45* on all 3 axes. So, looking at it from the front, the line where the chamfer starts is 45*. Same when looking from the right or the top. I'm pretty stupid when it comes to how to make compound angles

.

.Next challenge after figuring out what the angles are is how to mill it -- I first thought I'd just set the head of the manual mill to the right angles, but that's no good since the table is still going to move in plain old X and Y. Then I thought maybe I could get the angles right, then plunge an endmill into the corner, but that seems a bit sketchy.

Last resort is to just stick it in the VMC and let CAM figure it all out. But, I would like to know how to do this, in case I get something down the road that won't fit in the VMC or would be a PITA to fixture in the VMC.

Thanks, and regards.

Mike

,.

,. )

)

.

.