Hello everybody, my first post here.

Got this lathe from a gentleman who posted on Craigslist that lathe is free but needs to be removed from his basement. Turned out that this was a retired guy who lost his vision to the point of being legally blind so he couldn't operate the lathe anymore, but he said that lathe didn't own him anything and he just wanted it gone.

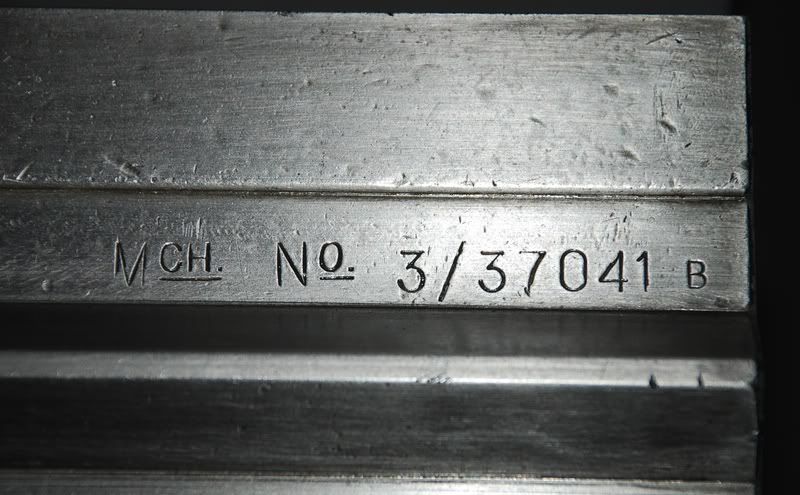

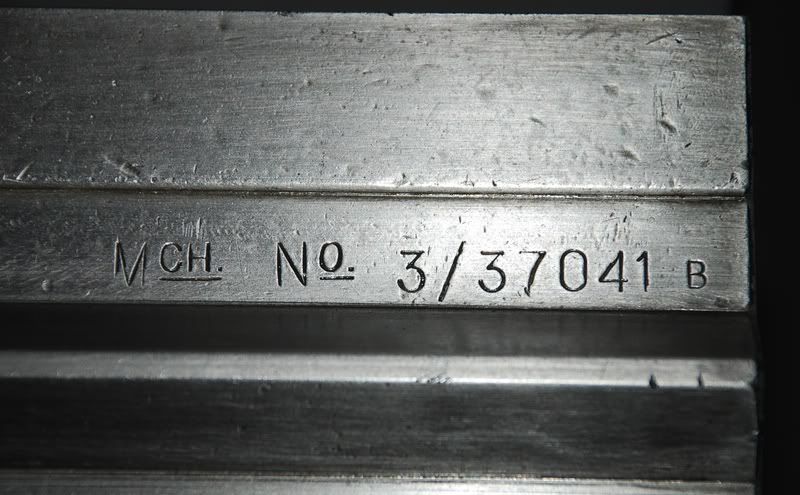

The lathe looks like Student/Master lathe from Tony’s web site, but I don’t know how to tell which exact model it is. The serial on it is 3/37041 B. Looks like it was made in 1960.

Here is a full set of pictures for the following discussion:

http://s290.photobucket.com/albums/ll259/Sinij_kot/Clausing Colchester 13x36 lathe/

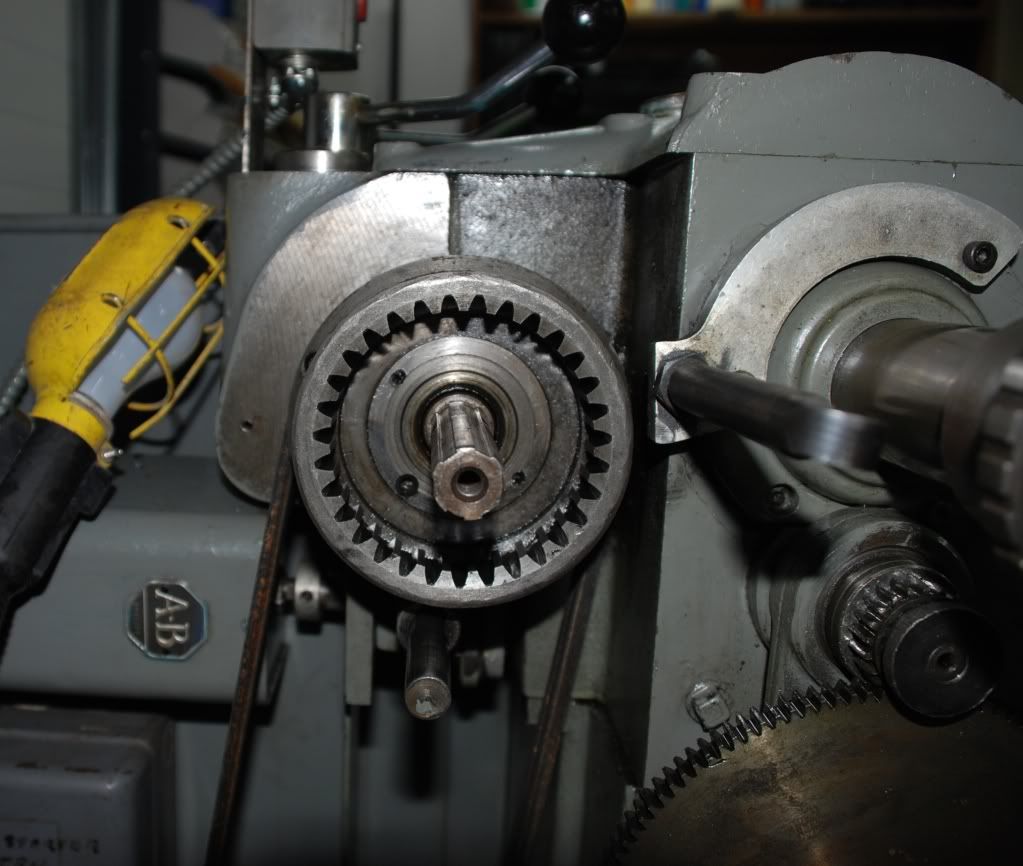

The lathe has few issues but was still usable when removed. The first problem had to do with Matrix clutch. He thought that the clutch was worn out. Turns out that someone tried permanently engaging the clutch by maxing out a clutch fork but it was slipping a bit. I decided to fully disassemble it and make it right. Once the clutch was removed I noticed that the clutch assembly bottomed out on the flange and rubbed against the pulley retaining nut.

It ate into the oil seal body as well. The seal was leaking, so I decided to remove the belt pulley to replace the seal. Once that was out I noticed that the clutch shaft had about .25" axial play, so I pulled the shaft out as well. What I found was a badly worn out inner bushing for the driving shaft. The driving shaft was also pretty badly worn.

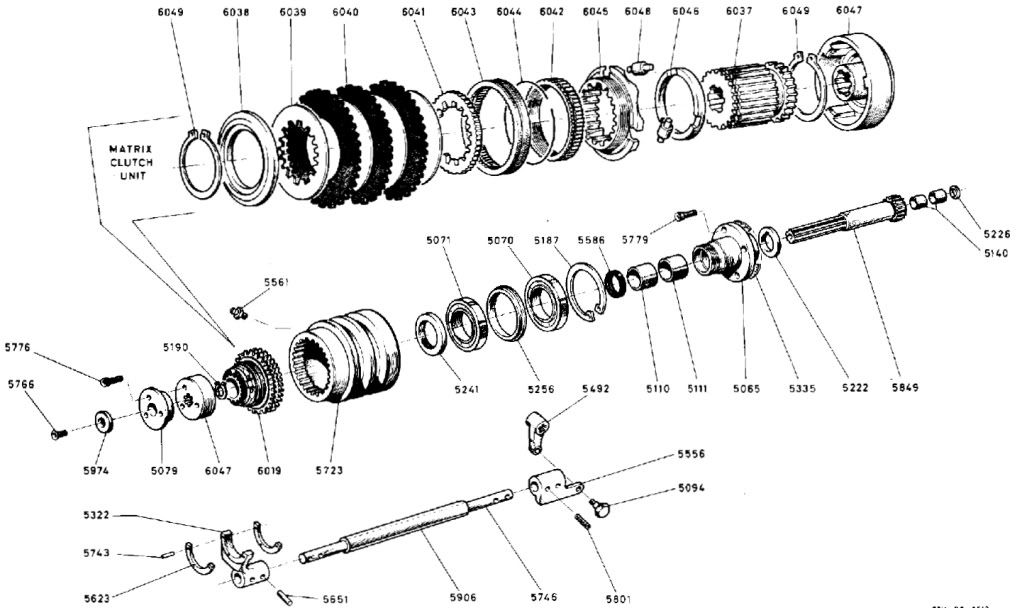

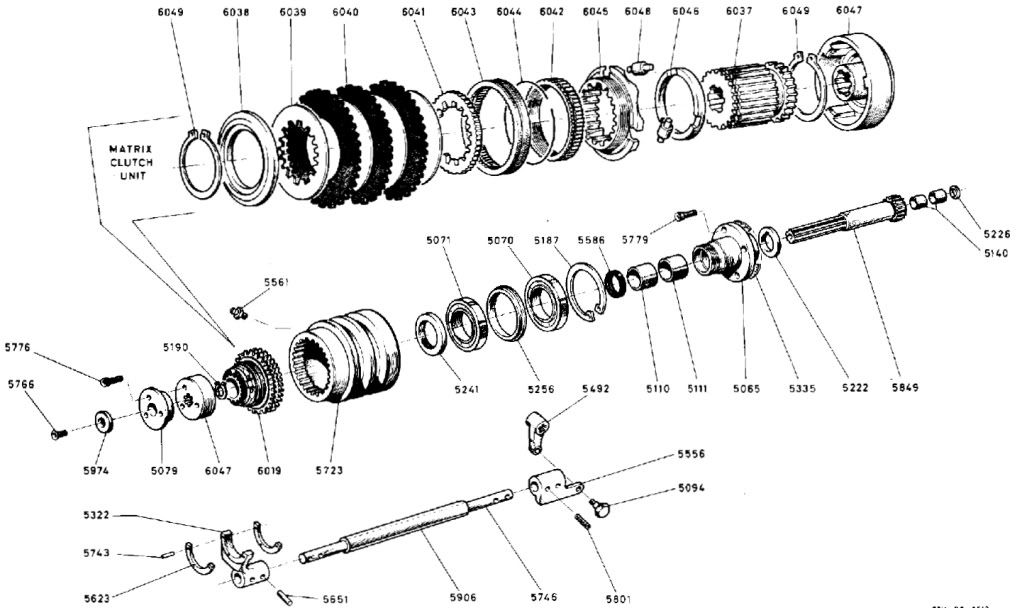

It was pretty obvious that someone was here before me and actually did a pretty bad job of trying to fix whatever problem there was. A little investigation revealed that one of the trust washers was left out and I think is was the cause of the excessive axial play which caused the clutch shaft to bottom out in turn producing metal shavings and destroyed the bushing and the shaft. The trust washed which is missing is 5226 part in the following diagram:

I received a quote for some of the parts that I need to fix the lathe and I thought that they were ridiculously high. For example couple of simple sleeve bronze bushings were 400$. The trust washer was 80$. The shafts were what a used lather goes for.

So I decided to have the shaft ends ground down and make new undersize bushings. I still need to get this 5226 trust washer and was hopping that someone here may have one or can provide its dimensions. I would consider getting the clutch shaft and the driving shaft as well just to replace it if the price is good. The clutch shaft especially concerns me because the teeth on it were built up and reground, but is looks pretty bad like a kid with a file got a hold of it. I am sure it is not meshing properly but I decided to live with it unless I can find a replacement.

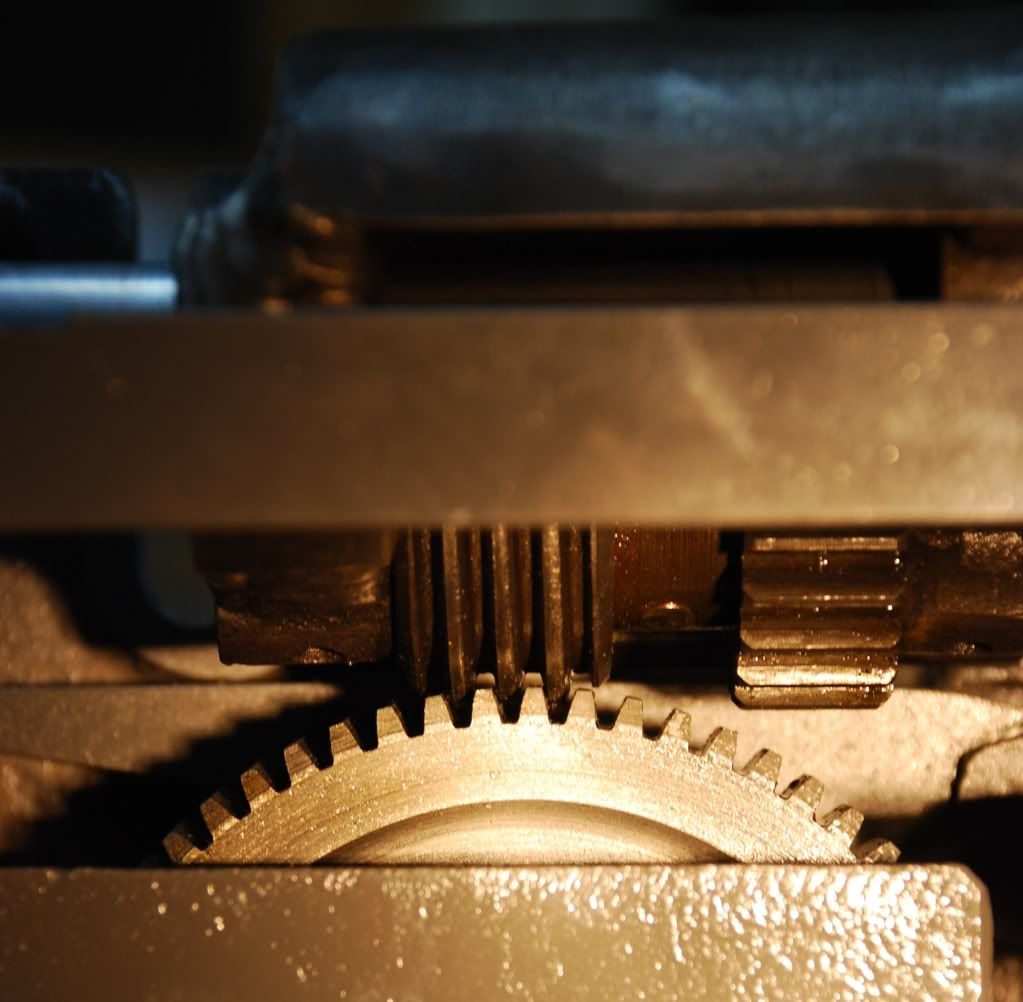

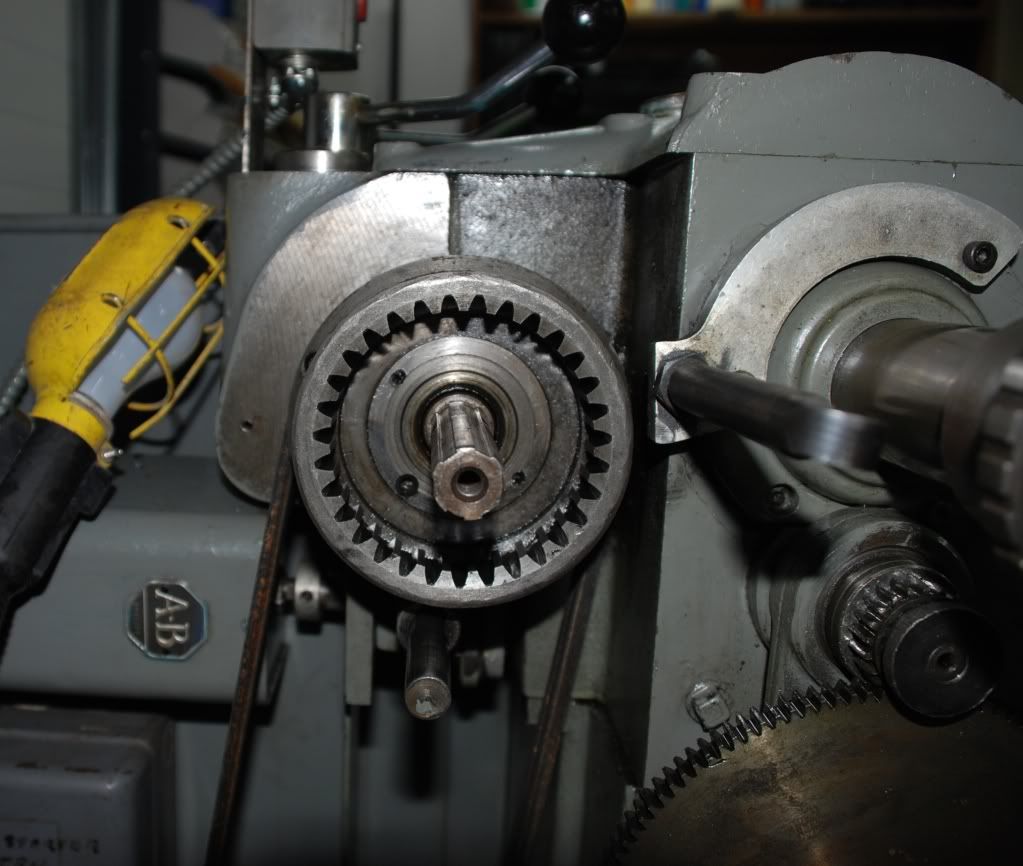

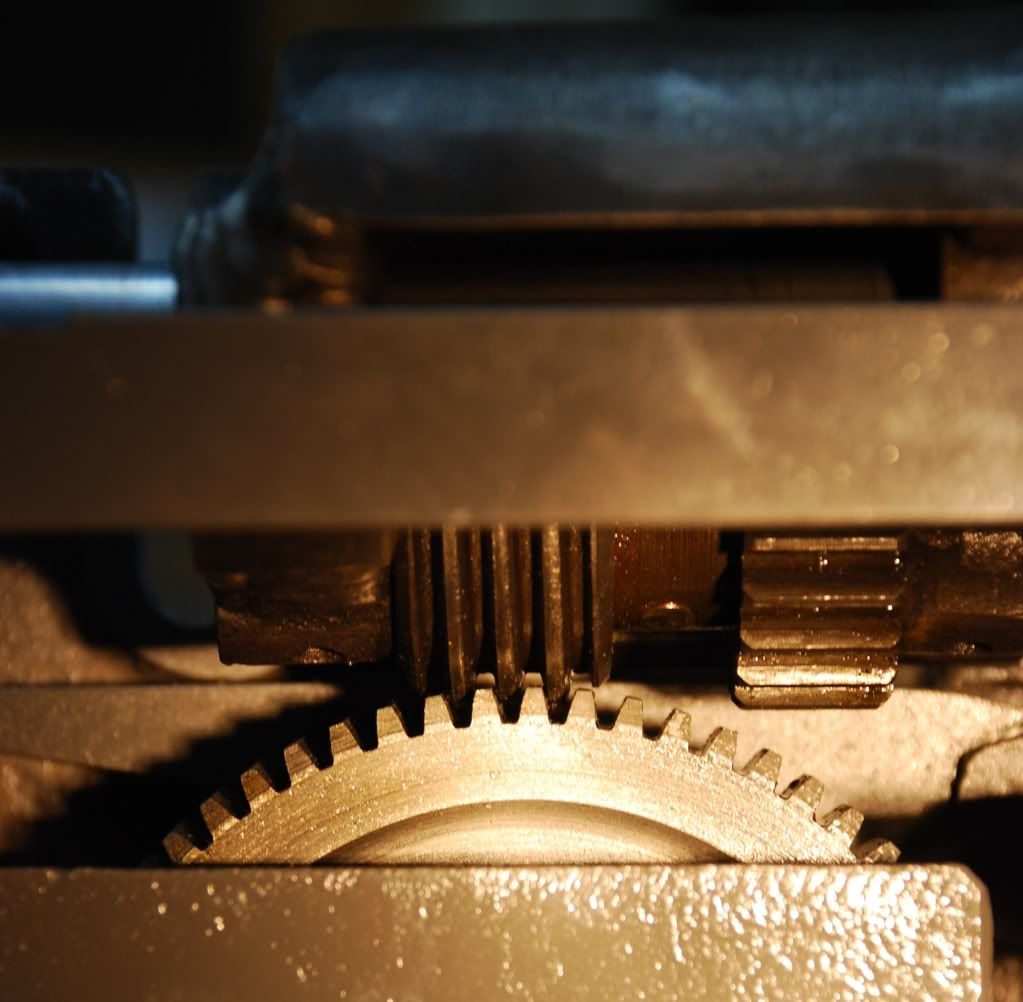

The second issue has to do with apron worm box. Someone was here too. The original owner did mention that when he got the lathe, shortly after the sliding worm gear had some teeth strip out, he went back to where he got it from and they made a new gear. The sliding wheel had a lot of play in it so I decided to take a look. Turns out that the pinion and the worm gears are not set up correctly and that is probably what cause the gear failure in the first place. Take a look at this:

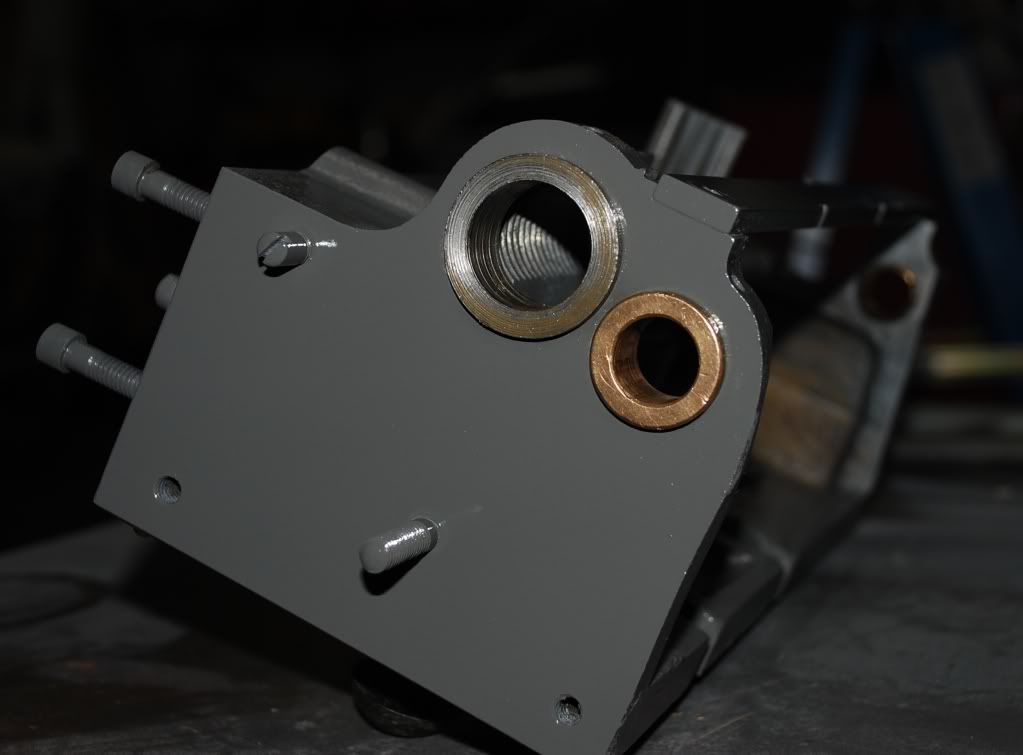

The teeth are engaging only by half and this is a main reason for excessive play in the hand wheel. So I started looking for why this might be. It looks like for whatever reason one of the worm box bushings was relocated which changed the gear alignment. I am still not sure why this was done. Did it break and was repaired or did someone try correcting a problem by relocating a bushing? Here are few views:

It appears that it the bushing was in the original position things would be in proper alignment. So I am looking to replace the worm box if I can find one.

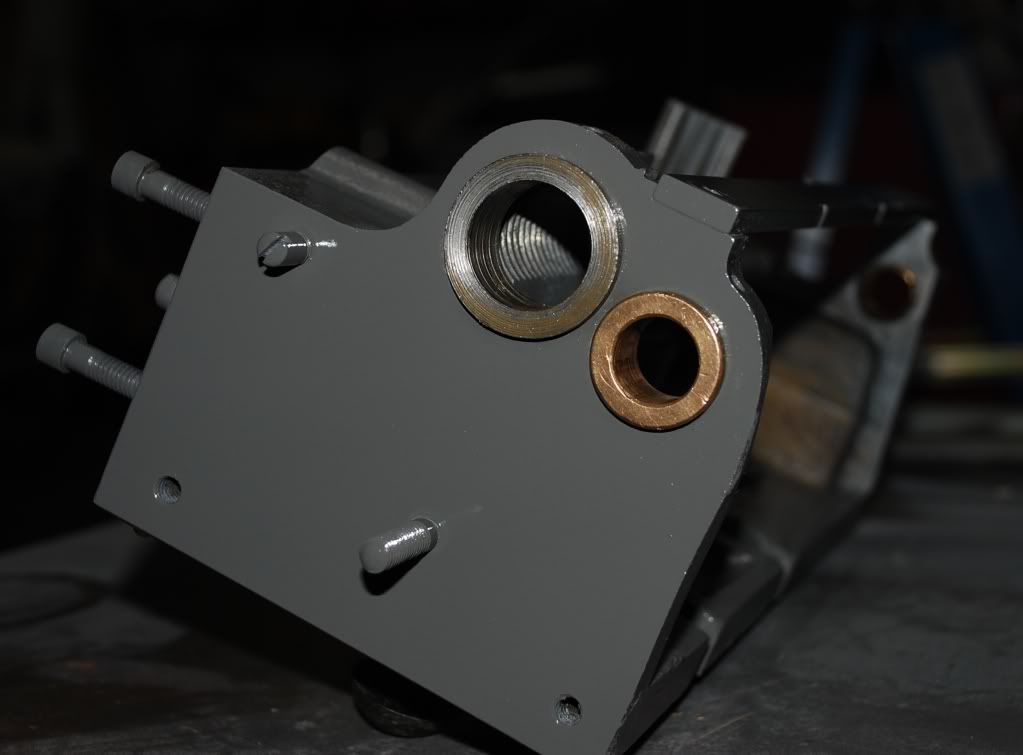

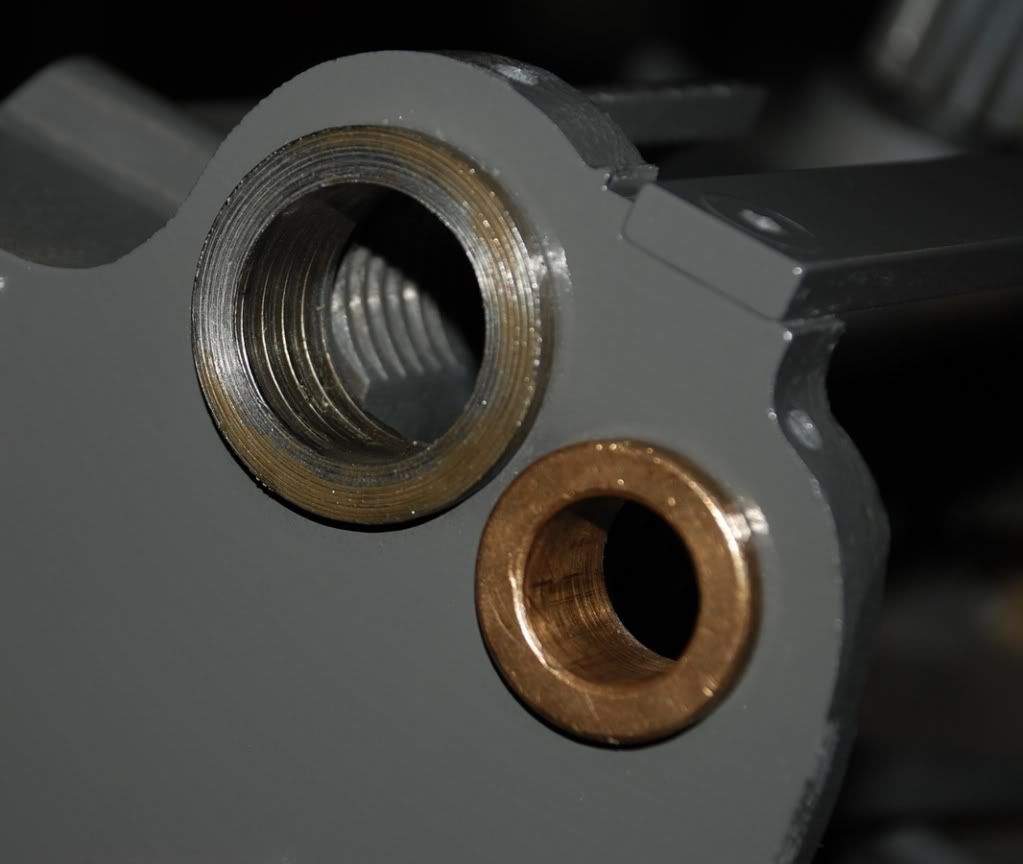

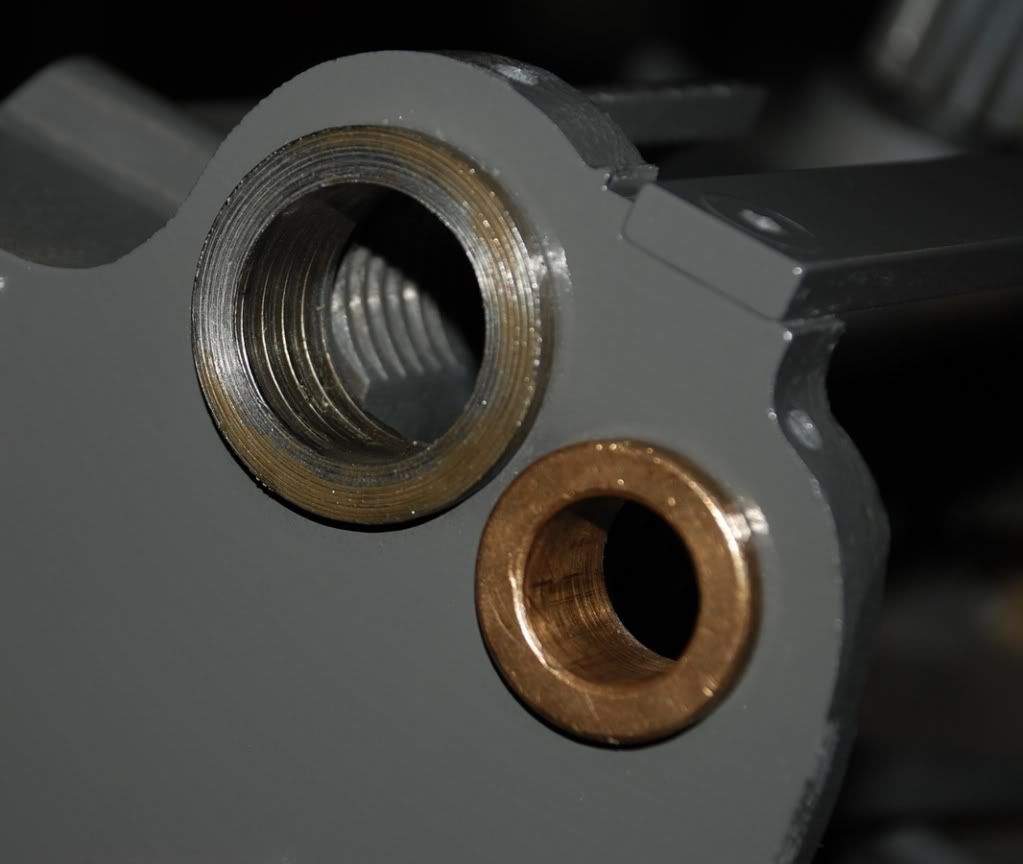

There is one other thing that I want to replace which is a metal bushing for the screw shaft, but I don’t know what material I should make it out of. Here are pictures:

I still have to get into the saddle to inspect / clean / adjust. Will see what other issues there might be.

So here is a list of parts I need for this machine:

Apron worm box

5226 Driving shaft thrust collar

5856 Driving shaft

5849 Clutch driving shaft

5347 driving shaft gear

When I got the lathe I decided to paint the pan because it looked pretty bad, but once I got into it, the whole thing ended up getting new paint.

I used TSC Valspar implement enamel in MF Gray. While I was at it I painted my cyclone dust separator. Turned out great!

Sorry for a very long post, and thanks in advance for any information, advise or parts that you can provide or help me locate.

Got this lathe from a gentleman who posted on Craigslist that lathe is free but needs to be removed from his basement. Turned out that this was a retired guy who lost his vision to the point of being legally blind so he couldn't operate the lathe anymore, but he said that lathe didn't own him anything and he just wanted it gone.

The lathe looks like Student/Master lathe from Tony’s web site, but I don’t know how to tell which exact model it is. The serial on it is 3/37041 B. Looks like it was made in 1960.

Here is a full set of pictures for the following discussion:

http://s290.photobucket.com/albums/ll259/Sinij_kot/Clausing Colchester 13x36 lathe/

The lathe has few issues but was still usable when removed. The first problem had to do with Matrix clutch. He thought that the clutch was worn out. Turns out that someone tried permanently engaging the clutch by maxing out a clutch fork but it was slipping a bit. I decided to fully disassemble it and make it right. Once the clutch was removed I noticed that the clutch assembly bottomed out on the flange and rubbed against the pulley retaining nut.

It ate into the oil seal body as well. The seal was leaking, so I decided to remove the belt pulley to replace the seal. Once that was out I noticed that the clutch shaft had about .25" axial play, so I pulled the shaft out as well. What I found was a badly worn out inner bushing for the driving shaft. The driving shaft was also pretty badly worn.

It was pretty obvious that someone was here before me and actually did a pretty bad job of trying to fix whatever problem there was. A little investigation revealed that one of the trust washers was left out and I think is was the cause of the excessive axial play which caused the clutch shaft to bottom out in turn producing metal shavings and destroyed the bushing and the shaft. The trust washed which is missing is 5226 part in the following diagram:

I received a quote for some of the parts that I need to fix the lathe and I thought that they were ridiculously high. For example couple of simple sleeve bronze bushings were 400$. The trust washer was 80$. The shafts were what a used lather goes for.

So I decided to have the shaft ends ground down and make new undersize bushings. I still need to get this 5226 trust washer and was hopping that someone here may have one or can provide its dimensions. I would consider getting the clutch shaft and the driving shaft as well just to replace it if the price is good. The clutch shaft especially concerns me because the teeth on it were built up and reground, but is looks pretty bad like a kid with a file got a hold of it. I am sure it is not meshing properly but I decided to live with it unless I can find a replacement.

The second issue has to do with apron worm box. Someone was here too. The original owner did mention that when he got the lathe, shortly after the sliding worm gear had some teeth strip out, he went back to where he got it from and they made a new gear. The sliding wheel had a lot of play in it so I decided to take a look. Turns out that the pinion and the worm gears are not set up correctly and that is probably what cause the gear failure in the first place. Take a look at this:

The teeth are engaging only by half and this is a main reason for excessive play in the hand wheel. So I started looking for why this might be. It looks like for whatever reason one of the worm box bushings was relocated which changed the gear alignment. I am still not sure why this was done. Did it break and was repaired or did someone try correcting a problem by relocating a bushing? Here are few views:

It appears that it the bushing was in the original position things would be in proper alignment. So I am looking to replace the worm box if I can find one.

There is one other thing that I want to replace which is a metal bushing for the screw shaft, but I don’t know what material I should make it out of. Here are pictures:

I still have to get into the saddle to inspect / clean / adjust. Will see what other issues there might be.

So here is a list of parts I need for this machine:

Apron worm box

5226 Driving shaft thrust collar

5856 Driving shaft

5849 Clutch driving shaft

5347 driving shaft gear

When I got the lathe I decided to paint the pan because it looked pretty bad, but once I got into it, the whole thing ended up getting new paint.

I used TSC Valspar implement enamel in MF Gray. While I was at it I painted my cyclone dust separator. Turned out great!

Sorry for a very long post, and thanks in advance for any information, advise or parts that you can provide or help me locate.