bjorn toulouse

Titanium

- Joined

- Dec 26, 2007

- Location

- N.E. oHIo, USA

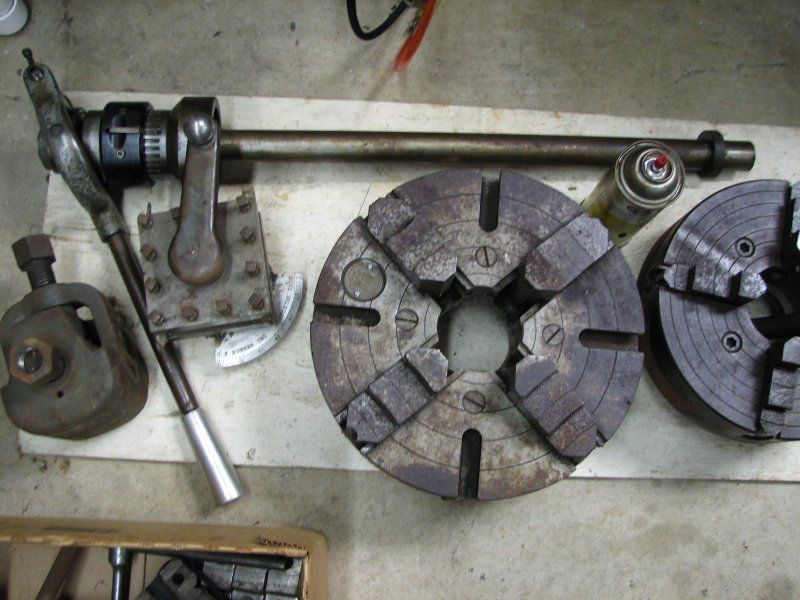

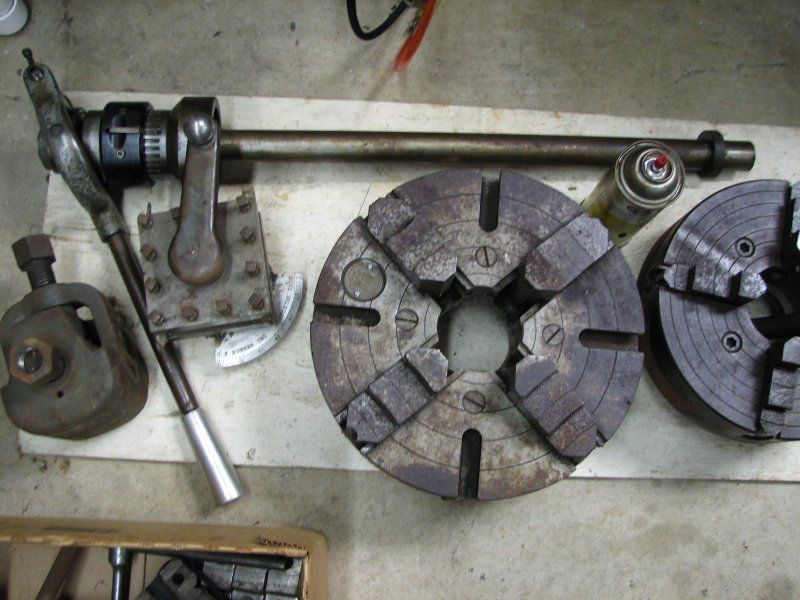

I bought a Sheldon R15 lathe last weekend (yeah, I know, no pics it didn't happen  ) and will be moving it to its new home this weekend. In the mean time, I do have pics of the extra 3 chucks (a relatively clean Buck 8" adjust-tru is on the lathe), a 5C collet closer, a hell-for-stout Globe boring bar holder and a nice, chunky 4-way tool post.

) and will be moving it to its new home this weekend. In the mean time, I do have pics of the extra 3 chucks (a relatively clean Buck 8" adjust-tru is on the lathe), a 5C collet closer, a hell-for-stout Globe boring bar holder and a nice, chunky 4-way tool post.

Here's the pics, questions follow,

The 12" 4jaw is a Cushman, the 10" 4jaw is of unknown mfg., and the 10" 3jaw is a Buck adjust-tru.

Does anyone have a clue as to the possible maker of the 10" 4jaw? I cannot see any markings on the chuck, it only has 4 cam lock pins on the back plate (same pin size and circle diameter as the others), and the square on the jaw wrench measures .280" across the flats.

These chucks, and the lathe itself, have been unused in an unheated NE oHIo garage for the past 5 or so years, so there is considerable surface oxidation to be dealt with. My biggest concern is the 10" Buck. The chuck is solid. I have been soaking it with PB Blaster and tapping on the jaws with a big no-bounce hammer

Is there a better way to go about this? I have done a little scraping on the faces of the chucks with a stout gasket scraper, and some of the lighter surface rust is cleaning up, but there are patches on the Buck that are pretty bad.

Any tips will be greatly appreciated!

Thanx,

Rex

) and will be moving it to its new home this weekend. In the mean time, I do have pics of the extra 3 chucks (a relatively clean Buck 8" adjust-tru is on the lathe), a 5C collet closer, a hell-for-stout Globe boring bar holder and a nice, chunky 4-way tool post.

) and will be moving it to its new home this weekend. In the mean time, I do have pics of the extra 3 chucks (a relatively clean Buck 8" adjust-tru is on the lathe), a 5C collet closer, a hell-for-stout Globe boring bar holder and a nice, chunky 4-way tool post.Here's the pics, questions follow,

The 12" 4jaw is a Cushman, the 10" 4jaw is of unknown mfg., and the 10" 3jaw is a Buck adjust-tru.

Does anyone have a clue as to the possible maker of the 10" 4jaw? I cannot see any markings on the chuck, it only has 4 cam lock pins on the back plate (same pin size and circle diameter as the others), and the square on the jaw wrench measures .280" across the flats.

These chucks, and the lathe itself, have been unused in an unheated NE oHIo garage for the past 5 or so years, so there is considerable surface oxidation to be dealt with. My biggest concern is the 10" Buck. The chuck is solid. I have been soaking it with PB Blaster and tapping on the jaws with a big no-bounce hammer

Is there a better way to go about this? I have done a little scraping on the faces of the chucks with a stout gasket scraper, and some of the lighter surface rust is cleaning up, but there are patches on the Buck that are pretty bad.

Any tips will be greatly appreciated!

Thanx,

Rex

Last edited: