twabscs

Aluminum

- Joined

- May 7, 2012

- Location

- NW Missouri

Hi All,

I know, my first post, but I've been lurking for a long time. Learning to do machine work a little at a time as I "purchased" an existing shop as part of a farm recently (IOW, it came with the farm). Anyway, we do mostly machine screw work but lots of other odds and ends.

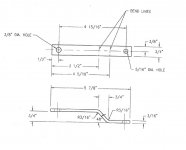

My question regards bending stainless. We have a Baileigh Industrial "pipe" bender with the universal plate. However, bending 3/16" stainless bar really stresses it and it is bent up pretty bad. For just a hundred or so pieces, what is the best way to create the part shown in the print.

The bend is the tricky part.

Thanks,

Tom

I know, my first post, but I've been lurking for a long time. Learning to do machine work a little at a time as I "purchased" an existing shop as part of a farm recently (IOW, it came with the farm). Anyway, we do mostly machine screw work but lots of other odds and ends.

My question regards bending stainless. We have a Baileigh Industrial "pipe" bender with the universal plate. However, bending 3/16" stainless bar really stresses it and it is bent up pretty bad. For just a hundred or so pieces, what is the best way to create the part shown in the print.

The bend is the tricky part.

Thanks,

Tom