CNCBurnout

Plastic

- Joined

- Oct 6, 2017

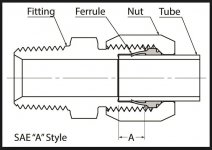

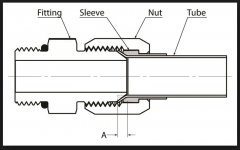

I'm trying to replace all the soft lines on a hydraulic fixture with hard lines but I'm not sure if I ordered the right fittings or maybe I'm to dense to see what I'm doing wrong. From the hydraulic component I have a male JIC 37 degree fitting that i want to go into a 1/4" hard line. Both fittings are from Vektek. The ferrule (sleeve) is 30-5000-44 and the nut is 30-4000-44. I flared a test piece of tubing and when I slip on the sleeve and nut I don't have enough thread to start the hard line onto the hydraulic components fitting. Shouldn't the sleeve fit thru the nut?

![20180118_164923[1].jpg 20180118_164923[1].jpg](https://www.practicalmachinist.com/forum/data/attachments/183/183392-469d5b20382e54c923b1d654ea9f673f.jpg)

I'm going going off of memory of AN fittings that I use to use for my wanna be fast race car but what I have here doesn't seem close to being right.

Other dumb questions

Should I double flare it? Can you double flare a 37 degree? Is the sleeve even necessary?

Thanks for reading!

![20180118_164923[1].jpg 20180118_164923[1].jpg](https://www.practicalmachinist.com/forum/data/attachments/183/183392-469d5b20382e54c923b1d654ea9f673f.jpg)

I'm going going off of memory of AN fittings that I use to use for my wanna be fast race car but what I have here doesn't seem close to being right.

Other dumb questions

Should I double flare it? Can you double flare a 37 degree? Is the sleeve even necessary?

Thanks for reading!