dsergison

Diamond

- Joined

- Oct 23, 2003

- Location

- East Peoria, IL, USA

an H-frame press, but with off-side capability. so you can get oversize stuff like riveting pannels, etc...

something I plan to do is buy some ironworker punches, (whatever is easy to find) and make a slideway that can attach to the upright to act as a linear guide powered by the ram.

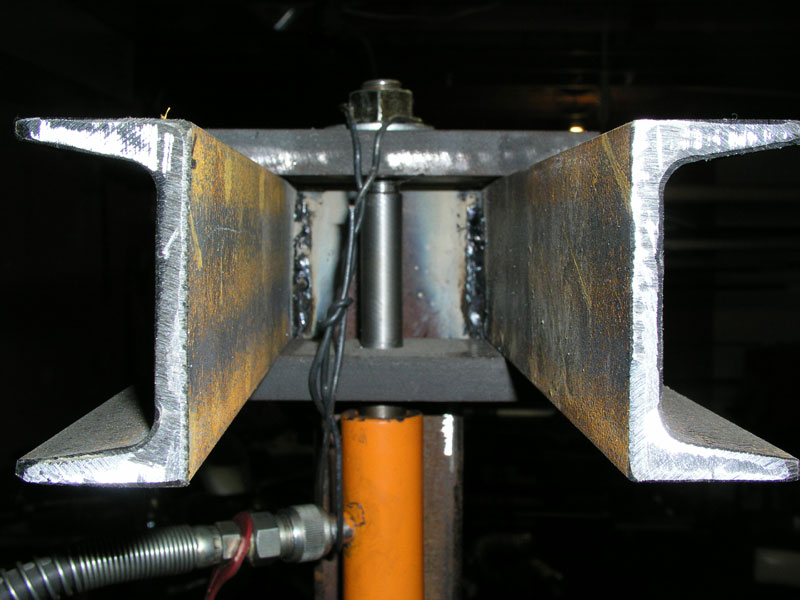

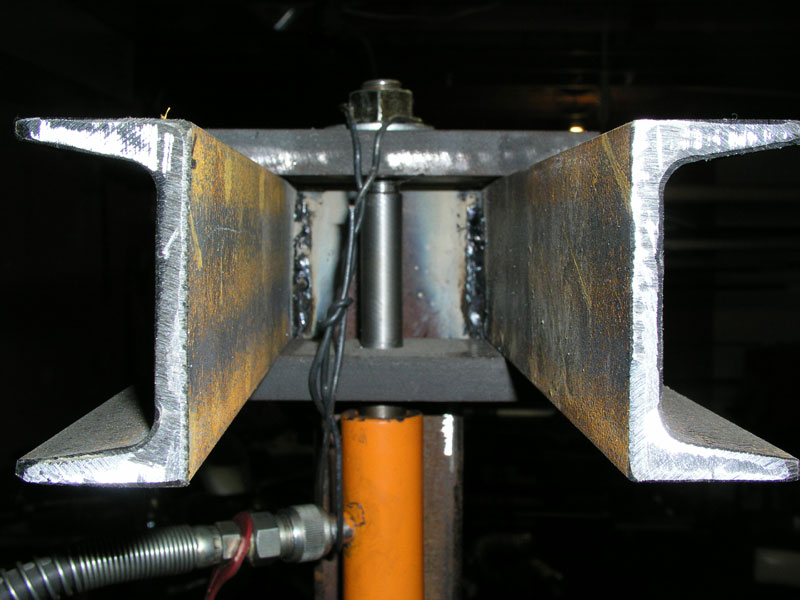

origionally the bridge and table were 3" x 3" x 1/4" angle. (what i had at the time) but it was rather springy. I backed that up with c3x5lb channel just tonight. now I cant get 1/8" deflection with ALL the ram power I can manage. almost 3x the section stiffness with the two of them. only the channel runs outboard. that capability was a recent improvement

have my shear clamped on it at the moment. good place to keep it handy.

something I plan to do is buy some ironworker punches, (whatever is easy to find) and make a slideway that can attach to the upright to act as a linear guide powered by the ram.

origionally the bridge and table were 3" x 3" x 1/4" angle. (what i had at the time) but it was rather springy. I backed that up with c3x5lb channel just tonight. now I cant get 1/8" deflection with ALL the ram power I can manage. almost 3x the section stiffness with the two of them. only the channel runs outboard. that capability was a recent improvement

have my shear clamped on it at the moment. good place to keep it handy.