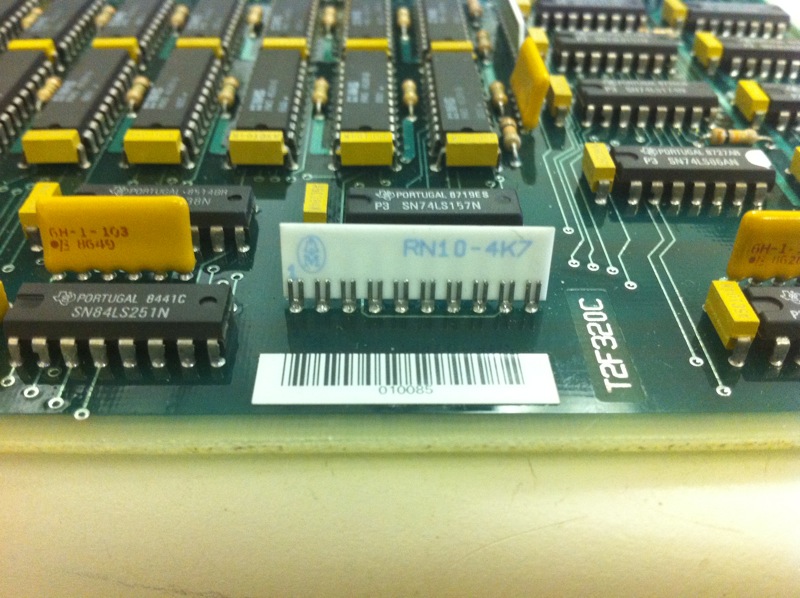

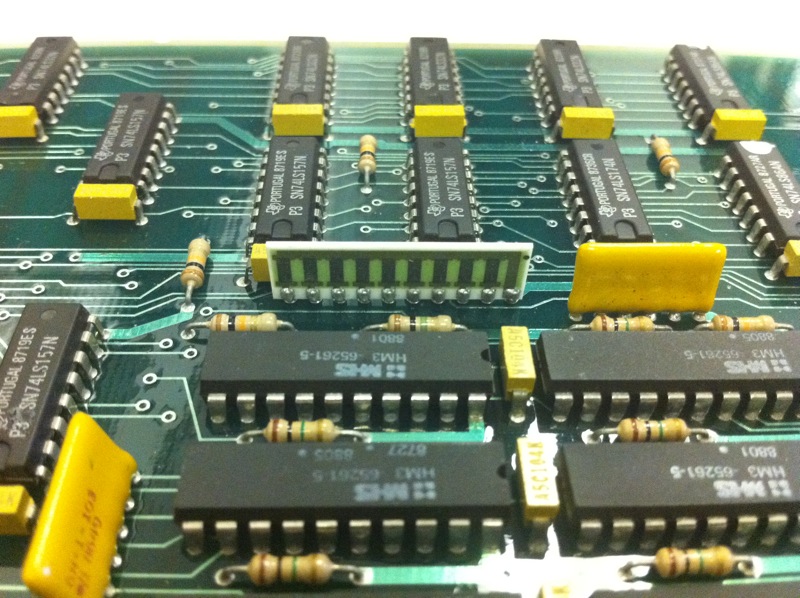

I need HC611002G and HC014701G.... this from 1991 vintage CNC control. Unlike even the most obsolete and obscure DIP IC, Google brings up nothing on these part numbers...

not even the usual fake electronic part sites offering to "quote" you in the hopes "you" are a huge company looking for 100,000+ pieces.

I've had this happen before with hybrid IC's...why are these little buggers so hard to find replacements for ? Does someone specialize in them ?

http://en.wikipedia.org/wiki/Hybrid_circuit

not even the usual fake electronic part sites offering to "quote" you in the hopes "you" are a huge company looking for 100,000+ pieces.

I've had this happen before with hybrid IC's...why are these little buggers so hard to find replacements for ? Does someone specialize in them ?

http://en.wikipedia.org/wiki/Hybrid_circuit