Lester Bowman

Hot Rolled

- Joined

- Apr 9, 2011

- Location

- Modesto california USA

Hi Guys.

I have recently registered to PM but have enjoyed learning here for years.It is by far the finest site I have ever found and there is something for everyone here.Thank You!

During the last eight years I have built two scale internal combustion engines.They are built to one third scale making them somewhat more than just a "model".I made all the patterns in Mahogany and had the castings made in cast iron.All the machineing techniques were old school done the old way because I wanted not only to experience the pleasure of creating a beautiful scale but also the sastisfaction of experiencing what the "old timers felt" when a difficult task was accomplished.

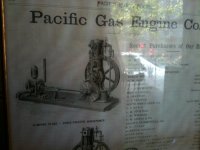

The first engine is a Samson gas engine originating in Stockton,Cal circa 1902.The second engine is a Pacific Vapor engine circa 1880 built in San Francisco cal. The flywheel diameter in 12" diameter on both engines.

If there is any interest in seeing pictures of these I will post them but I'm not sure the subject matter is appropiate in this forum.Is "General" the right forum or should these pictures perhaps be in the antique section?

I feel some of you would enjoy seeing these pictures because we all appreciate something well built by good tools and imagination.Thanks!

I have recently registered to PM but have enjoyed learning here for years.It is by far the finest site I have ever found and there is something for everyone here.Thank You!

During the last eight years I have built two scale internal combustion engines.They are built to one third scale making them somewhat more than just a "model".I made all the patterns in Mahogany and had the castings made in cast iron.All the machineing techniques were old school done the old way because I wanted not only to experience the pleasure of creating a beautiful scale but also the sastisfaction of experiencing what the "old timers felt" when a difficult task was accomplished.

The first engine is a Samson gas engine originating in Stockton,Cal circa 1902.The second engine is a Pacific Vapor engine circa 1880 built in San Francisco cal. The flywheel diameter in 12" diameter on both engines.

If there is any interest in seeing pictures of these I will post them but I'm not sure the subject matter is appropiate in this forum.Is "General" the right forum or should these pictures perhaps be in the antique section?

I feel some of you would enjoy seeing these pictures because we all appreciate something well built by good tools and imagination.Thanks!

She must be a very cool lady.

She must be a very cool lady.