I have some cast iron bars about 3x5 inches and 6 feet long, roughly.

Is that possible at all to cut them on a horizontal bandsaw?

I have a decent sized bandsaw but I am afraid whether cast iron may be abrasive to the blade.

I would need to make about 10 cuts.

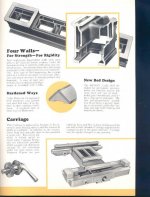

The bars 3x5in by 6ft are slides from a huge G&L horizontal mill. I wanted to cut them into pieces that would fit flat rate boxes and sell them.

Is that possible at all to cut them on a horizontal bandsaw?

I have a decent sized bandsaw but I am afraid whether cast iron may be abrasive to the blade.

I would need to make about 10 cuts.

The bars 3x5in by 6ft are slides from a huge G&L horizontal mill. I wanted to cut them into pieces that would fit flat rate boxes and sell them.