Bcmachinist

Plastic

- Joined

- May 10, 2017

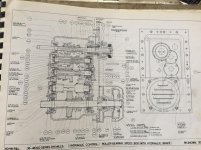

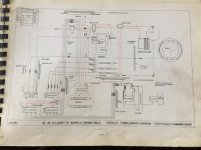

The shop picked up a used ,mid 80's I believe, Webster Bennett 48" boring mill. It didn't last long before it burned out the clutch plates... we replaced them, and immediately it burnt them out again... compared to the other boring mills in the shop, it seems like there is no slip when the start lever is engaged to turn the table. It seems like it's either on or off... where as the other machines you can ease it up to speed to prevent any abrupt start/stops. The oil pressure is up around 240... any have any experience with these machines and can point me in the right direction as to where to start looking for the issue? Thanks