Last edited:

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

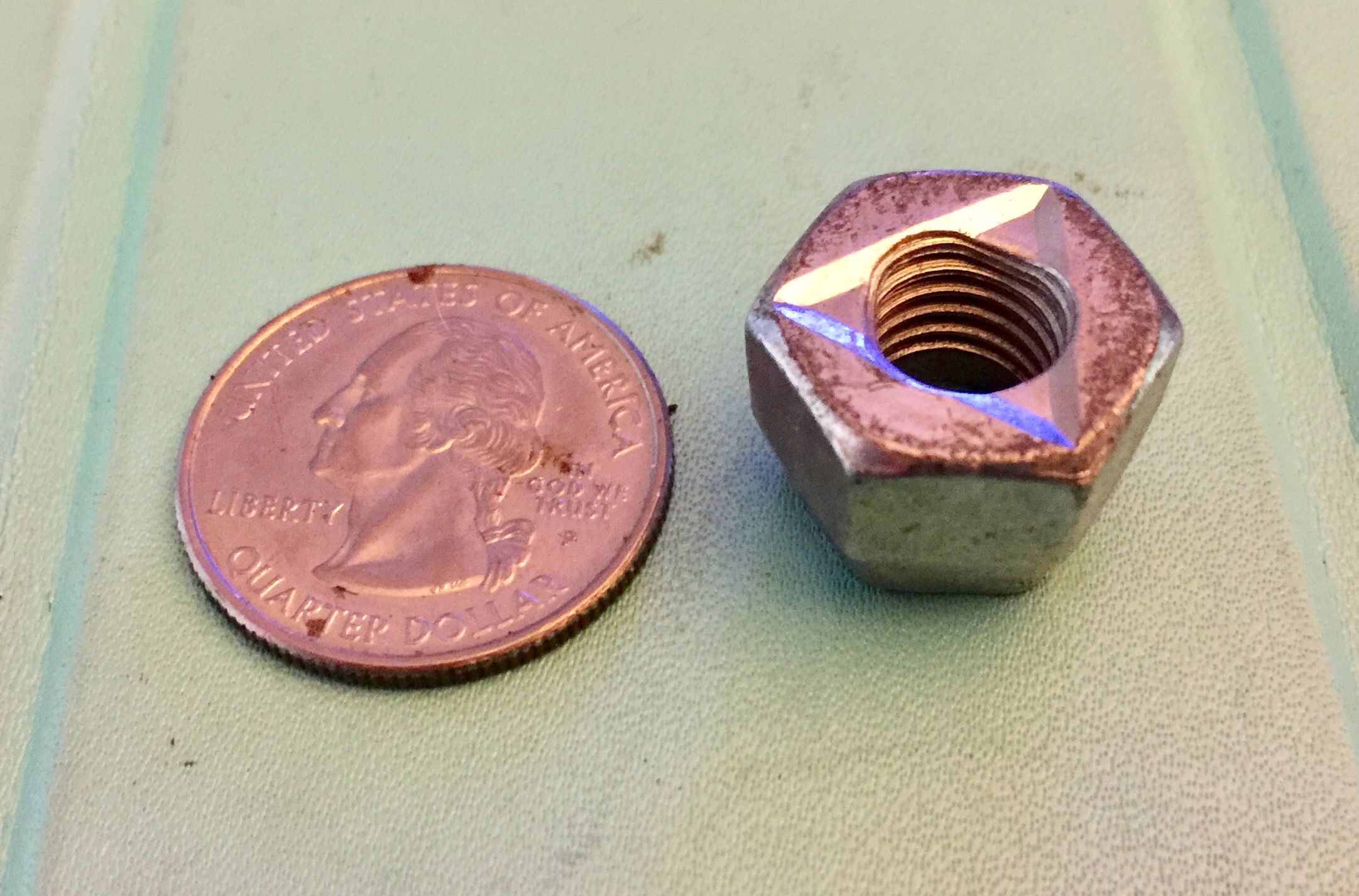

Yes rusty and dusty, will dunk in appropriate potions if worth the effort. Meanwhile there are a couple or few variants visible at top. Looks like base is cut so the ends of these will be parallel. Are these specials or some kind of machinist's tooling I may suddenly need 6 years from now?

Brings up a very good point.I worked in a school for a while. The kids had a name for those - " Gone Wrongs ".

Regards Tyrone.

Are you going to be starting a new thread for every one

of those bins you showed on a rack ?

Although I think I see some rust, you state that the angled cylindrical extensions re not corroded like the hex. Carbide-tipped inserts for some sort of digging device, like a trencher chain?

Easy enough to see if the tips are very hard. If so, you now have some boring-bar tips, or....

Although I think I see some rust, you state that the angled cylindrical extensions re not corroded like the hex. Carbide-tipped inserts for some sort of digging device, like a trencher chain?

Easy enough to see if the tips are very hard. If so, you now have some boring-bar tips, or....

My second thought was a replaceable tooth for digging/facing/trenching equipment of some sort.

I'm imagining a rotating drum or disk populated with many and beating the subject media into submission.

The slot could be to engage a retainer.

Even if they're not hard, they might be production over-run and not yet heat treated.

Too bad Cannonmn isn't bright or savvy enough to provide dimensions or even a common object for scale reference.

My first thought was "More 'what is it?' from that non-contributing, junk salvaging, digging for a bonanza, weasel Cannonmn."

Does that ring a bell with anyone?

Why, thank you! That's the nicest thing anybody's said about me all week!!

I'll be working up some more "please ID this junk" jest for u!!

Time "scrapped", and goodwill - damaged - are not so easily replaced.

Notice

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.