Foghorn

Plastic

- Joined

- Dec 8, 2011

- Location

- Midwest USA

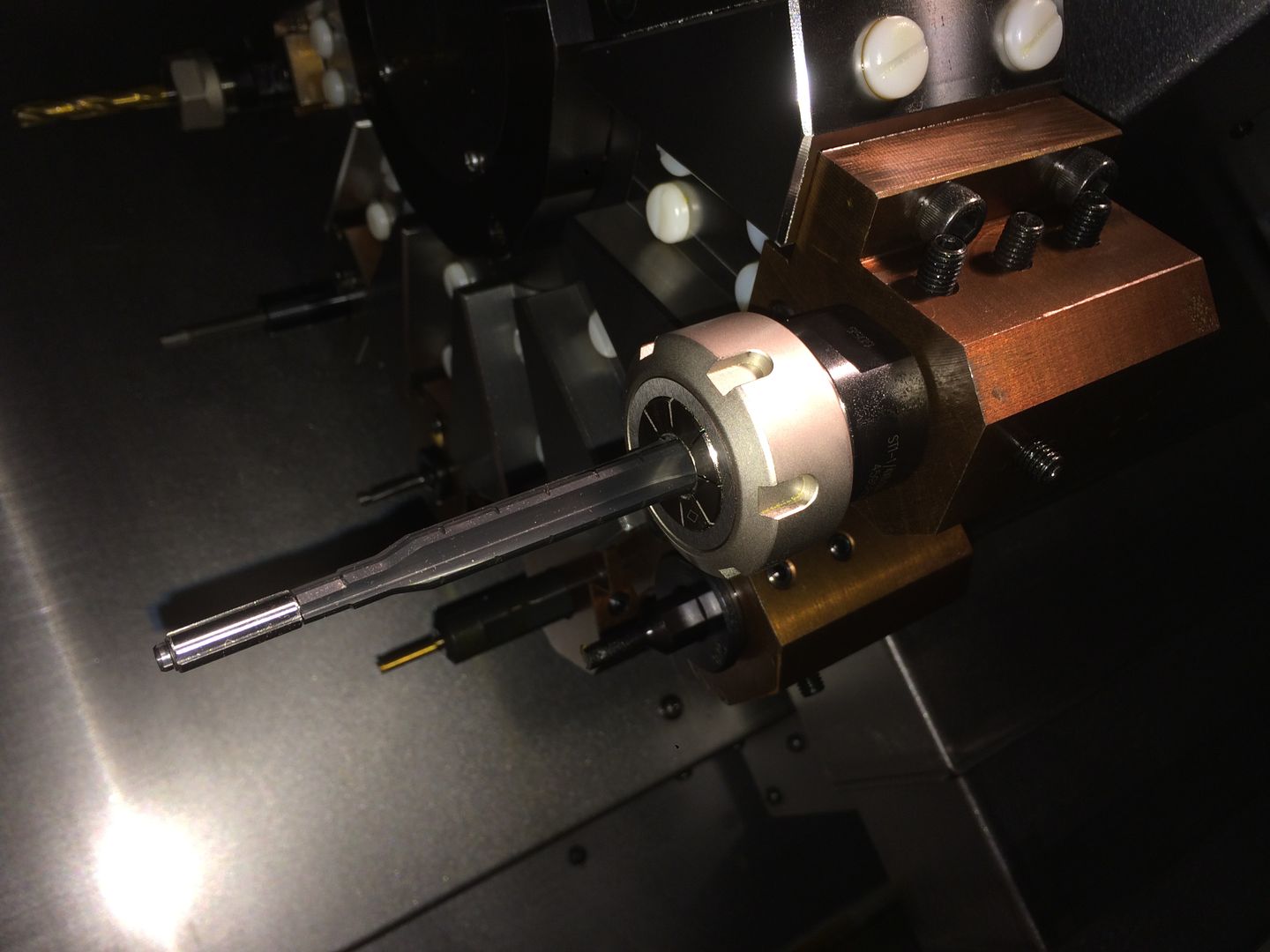

I just want to get a feel for what fixtures people are using to mount their chamber in reamers. Who is using the tailstock? Gang style tool post? Floating holders vs. Rigid? 5c collet adapter on the tool post? We are currently running a gang style holder bolted right to our cross feed, generally holding roughing reamers rigid and finish reamers in a JGS floating holder. But we are ready to explore some new possibilities