R

rawcustomknives

Guest

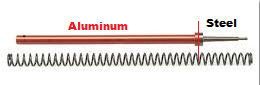

Long time lurker, first time poster. I've been toying with the idea of finding a speed pin for my CZ 550 in 22-250, problem is there doesn't seem to be any in standard production. However, it doesn't seem to be much of a job to fabricate one especially if you used the front steel (striker part of the pin) and threaded a replacement aluminum body behind it. Any ideas why this wouldn't work, and anyone on here up to the task?

Also I'm well aware of the minimal effects of toying with lock time, but it's something that does matter enough to me to toy with, so please don't bother with posts about "not worth it".

Thank you

Also I'm well aware of the minimal effects of toying with lock time, but it's something that does matter enough to me to toy with, so please don't bother with posts about "not worth it".

Thank you