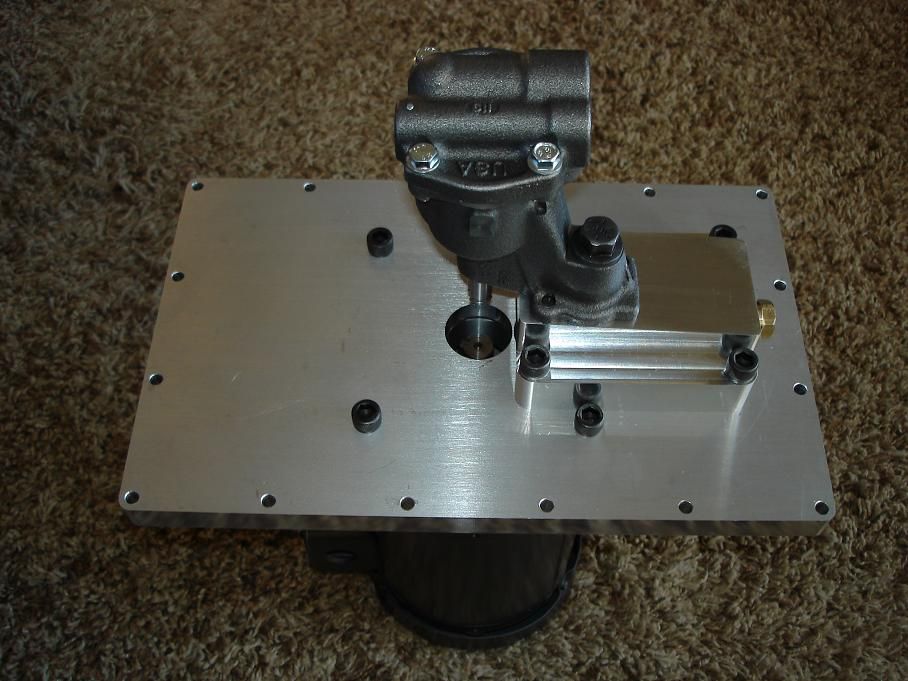

Basically all you need is to find an old hydraulic power pack and run cutting fluid in it and not hydraulic oil. You will also have to instal a simple oil filter in the input line to the pump. You can use whatever you want for tankage, granddaddy's ole war helmet for all I care, but you need an over pressure and/or over volume return line back to tankage as well as a return line from the lathe tray. These pumps create far to much pressure for your needs so you have to return a lot to tankage. If you want to make one, these are the 3 base components you will need. The motor, pump and coupler. You will also need a couple lovejoy or butterfly couplers to connect the two shafts and some hydraulic line and valves. You can also buy a commercial manifold to regulate flow and pressure or do it the crude way with valves. A rig like this will also power about a 6 ton shop press if you have an old cylinder kicking around and will also run log splitters, jaws of life, auto shears or whatever other hydraulic appliance you happen to have kicking around. They will not however supply enough oil to deep hole drill. You need 7/10 GPM for those things. These pumps are 1.5/2 GPM. I have seen guys cannibalize old power-packs from electric/hydraulic winches and build systems for $200. I have seen other guys scratch build them for $500 / $1,000. I turned down a hydraulic lathe tracing attachment in Ontario for $600 a couple years back because it was to big for my machines. Hind sight being 20/20 I should have bought it and scrapped the tracer. It came with a 3HP power pack all set up with tankage and hose's. If your neighbor has an electric hydraulic log splitter he wants to get out of for $100 you may have a perfect hydraulic power pack. Most of those units are about 1.5 GPM at 2000 to 3000 PSI but it's no problem to vent excessive pressure and flow back to tankage.

2.2 GPM Bi-Rotational Pump/Motor | Princess Auto

C-Face Electric Motor Pump Mounting Bracket | Princess Auto

2 HP Totally Enclosed Fan Cooled Electric Motor | Princess Auto

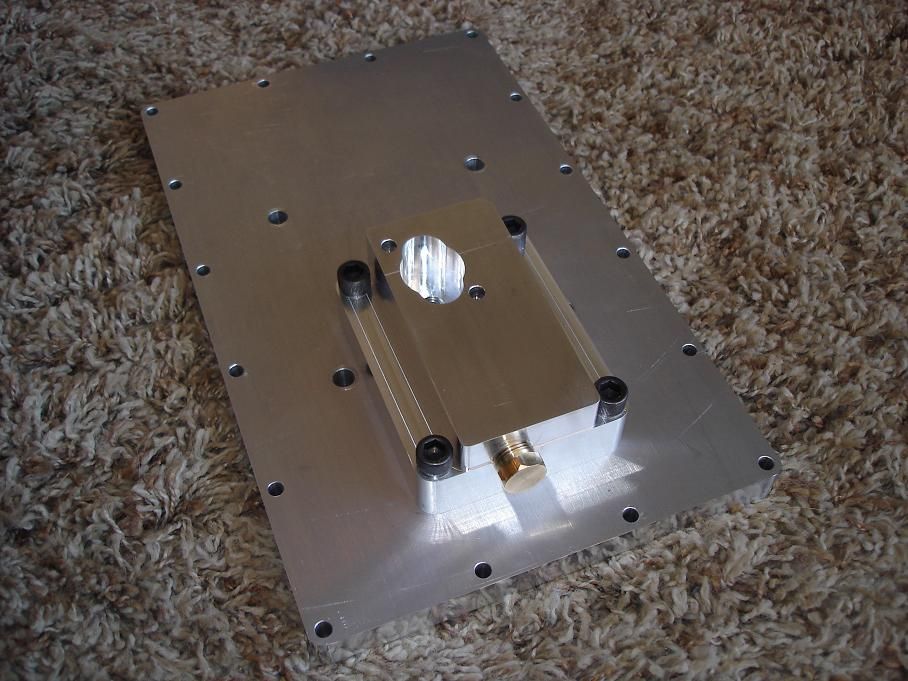

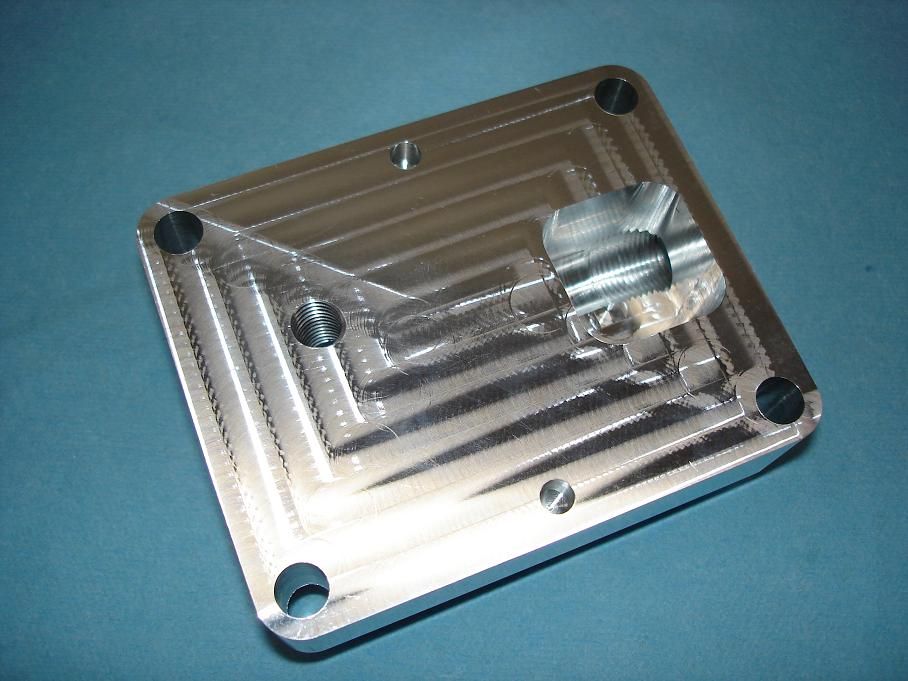

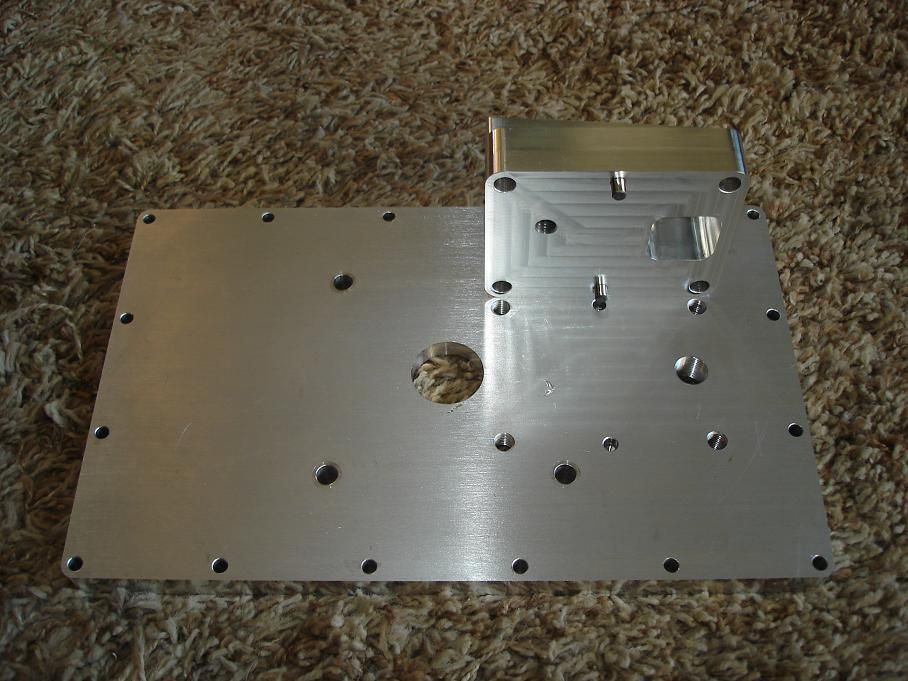

View attachment 90737View attachment 90736View attachment 90735

Anyway now you know what you are looking for.

ADD NOTE: I'm no hydraulics expert. I go on the old farmer measurement of 1HP of motor to each gallon per minute to get 1000 PSI. Going with two little motor tends to wreak motors. So a 2HP motor will work with a pump that size but it won't give the full 3000 PSI the pump is capable of producing. Probably more like 1000 to 1500 PSI at a full 2 GPM I think! But don't take my word for it. There must be a hydraulics eggspurt crawling around here some where.