G-Auto

Hot Rolled

- Joined

- Nov 13, 2006

- Location

- Montco, PA

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

I'd hope it will go slower than 35 RPM,however. You can't do large cast iron face plate work in the gap at that speed.

I'd hope it will go slower than 35 RPM,however. You can't do large cast iron face plate work in the gap at that speed.Kingston lathes are one of the best Asian lathes. I wouldn't mind having that one at all!!I'd hope it will go slower than 35 RPM,however. You can't do large cast iron face plate work in the gap at that speed.

I see they make a wall mount model, is a floor mount model available also?

(At least I put some smiley's in...)

(At least I put some smiley's in...)I see they make a wall mount model, is a floor mount model available also?

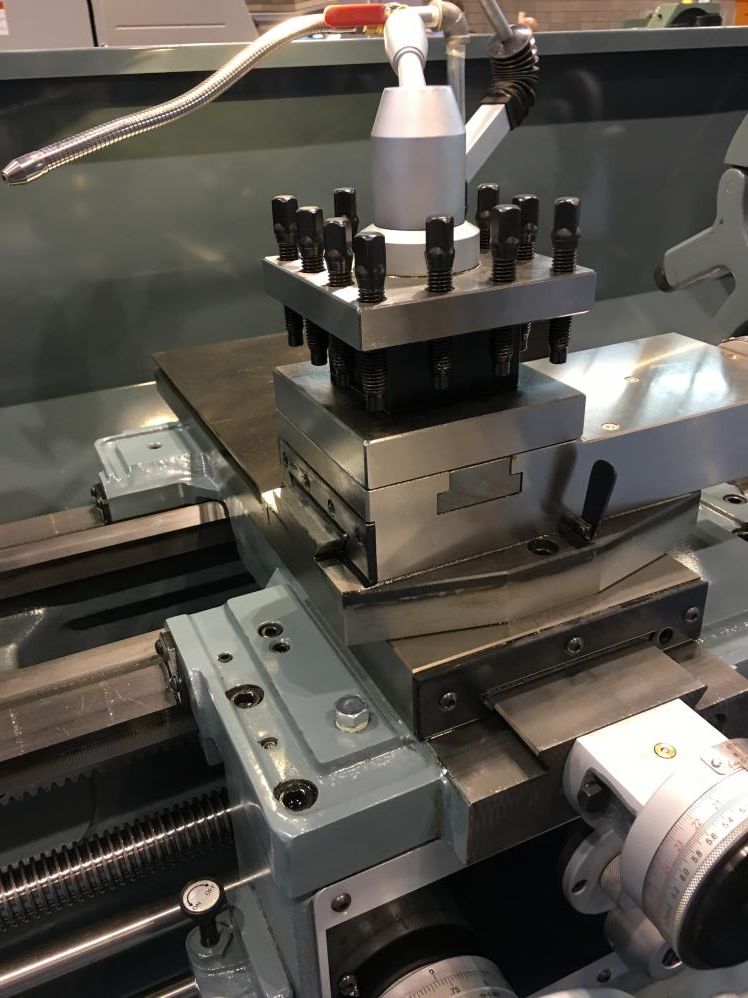

We've had two import lathes in the recent past that both had the same issue (an Enco and a Dashin Prince from MSC). Seems to be a trend of teaming a 15" lathes head stock up with a 10" lathes carriage.....That thing looks robust, I would like to see the carriage be about 50% wider. Cross feed and compound look a bit light as well.

Nice lathe, but not for gunsmithing. Too long in the headstock for chambering barrels in the headstock. Not for me and I'll bet they are not giving them away either.

I can't tell from pictures, but if it's the same as the Grizzly I ran a bit, the screws on the back side were in just the right place to hold a 16" barrel. With nothing to spare. Shorter than that, and you just have to make a fixture to put into the chuck.

That thing looks robust, I would like to see the carriage be about 50% wider. Cross feed and compound look a bit light as well.

I think it is much wider than that. I'll bet if you had a cathead on both ends a 22" may be the longest that it can do in the headstock.

Notice

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.