Let me start out by saying that I'm not a machinists. BUT!! I am a tool guy I have my on wood shop and I have a granite shop as well. So I'm not unfamiliar with tools by any means. if I were going to do this project out of stone or wood it would be no problem..

I do have a full machine shop to work with. I have a good friend that is a retired machinist and he has 3 huge end mills 2 lathes and quite a few other nice pieces of machinery. He will be helping me with this project but I want to do as much of it my self as I can because that's who I am. I like learning. SO why am I here if I have some one to help me? HE has been retired for 20 years and is a little fuzzy on the tooling needed. I don't think he did a lot with hardened steel

here is the project..

I just bought several glocks one of them being a glock 17. I want to modify the g17 so I need advice on tooling more than any thing.

This is a picture of the factory slide

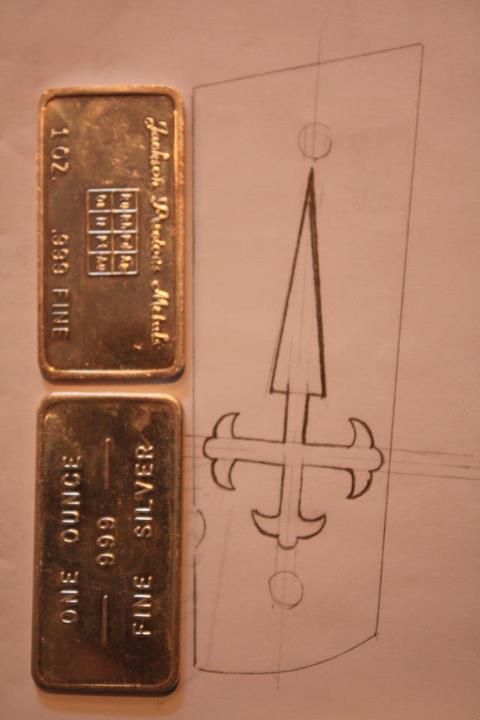

This is what I want to do to it

The rear of the slide needs to be milled out .125" and 2 holes need to be drilled and tapped. On the front of the slide I want to cut the notches to better cool it and take off a bit of weight..

I currently have a double fluted 1/2" solid carbide bit for the milling but I don't know if this is the best thing I have herd that it will work I have also heard that I want a 5 fluted end mill. I know that the slide is stainless and has a 64 Rothwell rating so here is the question..

what bit is rite for milling this?

I also need a 1/4" ball nose but for milling the notches on the front of the slide what is the best one for milling these notches?

I do have a full machine shop to work with. I have a good friend that is a retired machinist and he has 3 huge end mills 2 lathes and quite a few other nice pieces of machinery. He will be helping me with this project but I want to do as much of it my self as I can because that's who I am. I like learning. SO why am I here if I have some one to help me? HE has been retired for 20 years and is a little fuzzy on the tooling needed. I don't think he did a lot with hardened steel

here is the project..

I just bought several glocks one of them being a glock 17. I want to modify the g17 so I need advice on tooling more than any thing.

This is a picture of the factory slide

This is what I want to do to it

The rear of the slide needs to be milled out .125" and 2 holes need to be drilled and tapped. On the front of the slide I want to cut the notches to better cool it and take off a bit of weight..

I currently have a double fluted 1/2" solid carbide bit for the milling but I don't know if this is the best thing I have herd that it will work I have also heard that I want a 5 fluted end mill. I know that the slide is stainless and has a 64 Rothwell rating so here is the question..

what bit is rite for milling this?

I also need a 1/4" ball nose but for milling the notches on the front of the slide what is the best one for milling these notches?